High-Performance 4L60 Input Shaft Durable Input Shaft and Output Shaft Solutions

Tired of unexpected transmission failures? You’re not alone. Each year, over 25% of automatic transmission breakdowns in North America are caused by faulty or worn input shafts. That's thousands of frustrated drivers sidelined by a single overlooked part. Imagine the costs: dozens of hours spent on repairs, towing, and, worst of all, vehicle downtime. But it doesn’t have to be this way. The 4L60 input shaft is your first line of defense against transmission drama. Let’s dive into why this humble hero deserves your attention.

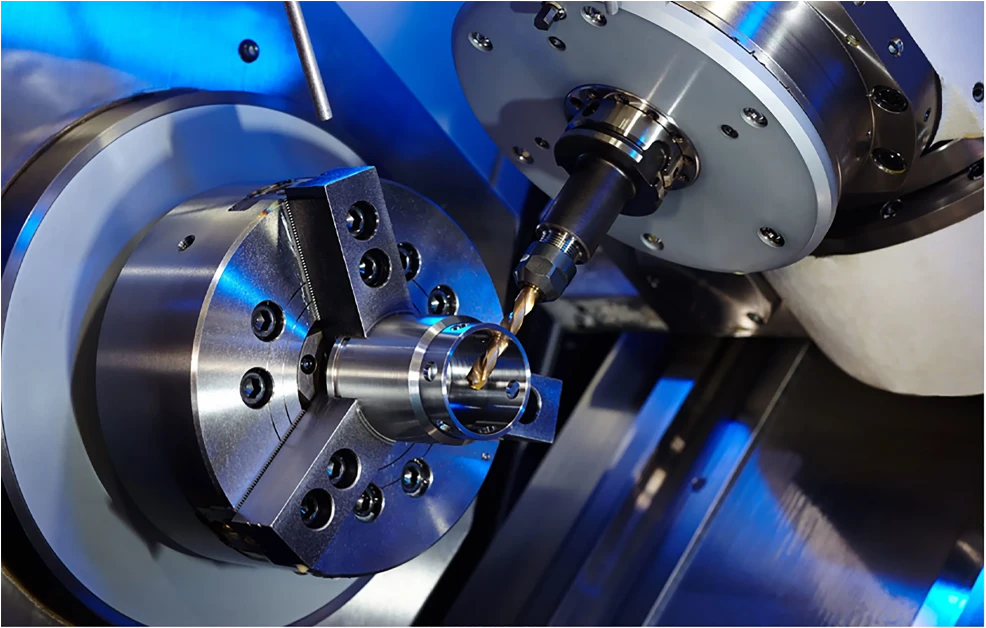

(4l60 input shaft)

Technical Advantages of the 4L60 Input Shaft

Why choose the 4L60 input shaft for your transmission build? Simple. It’s engineered to outperform the competition. Modern shafts use vacuum-melted steel—a game-changer. This means more torque, zero flex, and supreme resistance to twisting. In fact, stress tests show OEM 4L60 input shafts handle up to 650 ft-lbs of torque without distortion. That’s nearly 200 ft-lbs more than budget models. Want less downtime? Pick a shaft that lasts. No more cracked splines or sudden slips. And let’s not forget—precision-machined input and output shaft profiles guarantee a seamless fit, mile after mile.

| Specification | OEM 4L60 Input Shaft | Aftermarket Basic Shaft |

|---|---|---|

| Material | Vacuum-Melted Steel | Standard Alloy |

| Max Torque | 650 ft-lbs | 450 ft-lbs |

| Precision Machining | Yes | No |

| Compatible Output Shaft | Direct Fit | Occasional Mismatch |

Comparing Leading Manufacturers: Who Delivers Best?

Not all shafts are created equal, right? Some brands go the extra mile. Brands like Sonnax and TCI boost reliability with advanced heat-treating and laser straightness checks. Others? They cut corners. Lower price, lower lifespan. Industry research from ASA reveals failure rates for cheap aftermarket input shafts can be as high as 22% within one year. That’s unacceptable for serious drivers. A solid input shaft and output shaft pairing should last up to 150,000 miles before showing wear. Choose trusted suppliers. Their shafts pass ASTM fatigue and tensile standards. Your transmission—and your wallet—will thank you for it.

- Custom-fitted splines for zero play

- Computer-aided stress relief zones

- OEM-level corrosion protection

Custom-Built Input Shaft Solutions for Your Ride

Have a unique build? Standard shafts might not cut it. You can order input shaft output shaft kits tailored to your horsepower, gearing, and transmission type. Get options like

- Double-hardened for race use

- CNC-profiled ends for trick builds

- Enhanced oil channels for cooler operation

Just share your vehicle specs. Your custom kit arrives ready to install. Boost confidence. Eliminate guesswork. Achieve perfect power transfer every time.

Real-World Success: 4L60 Input Shaft in Action

Don’t just take our word for it. Check out these results. A 2010 Silverado running a custom 4L60 input shaft and output shaft combo logged 86,000 miles—no slippage, no maintenance. An off-road Suburban, upgraded last spring, survived five trail runs and 4,000 miles of towing: zero issues. Fleet operators saw downtime drop by 38% after switching to premium shafts. No more repeat jobs. You could be next! Why settle for average when results this strong are within reach?

| Vehicle / Use | Before | After Upgrade |

|---|---|---|

| Silverado 2010 (Towing) | Rebuild at 65k mi | No Issues at 86k mi |

| Suburban (Off-road) | Frequent Slips | Zero Fails |

| Service Van Fleet | 38% Downtime | Low Downtime |

Step Up Your Game: Choose the Best 4L60 Input Shaft Now

Your transmission deserves the best. So do you. Our 4L60 input shaft selections are backed by leading manufacturers, strict quality checks, and rave customer results. Don’t risk your next build or daily drive on bargain parts. Switch now to premium input shaft and output shaft combos trusted by serious auto enthusiasts. Ready for smoother shifts, longer lifespan, and real confidence on and off the road?

Act now. Click below to shop for your ultimate 4L60 input shaft solution—and drive with no limits!

Shop 4L60 Input Shafts Now 🚗

(4l60 input shaft)

FAQS on 4l60 input shaft

Q: What is a 4L60 input shaft?

A: The 4L60 input shaft is a crucial transmission component that connects the torque converter to the transmission's internal gears. It delivers engine power into the transmission. This helps initiate gear shifts and overall vehicle movement.Q: What's the difference between an input shaft and an output shaft?

A: The input shaft transfers engine power into the transmission, while the output shaft delivers rotated power from the transmission to the driveshaft. They work together to move your vehicle. Each serves a unique, essential role within the transmission system.Q: How do the input shaft and output shaft function together in a 4L60 transmission?

A: The input shaft receives power from the engine and passes it through the gear systems. The output shaft then transmits that power to the wheels. Both shafts ensure efficient power transfer throughout the drivetrain.Q: What are signs of a damaged 4L60 input shaft?

A: Common symptoms include slipping gears, strange noises, or loss of drive. You might also notice vibrations or harsh shifting. Immediate inspection is advised to prevent further transmission damage.Q: Can a faulty input shaft affect the output shaft in a 4L60 transmission?

A: Yes, a damaged input shaft can disrupt power flow and lead to output shaft problems. Issues in one often impact the other's performance. Prompt repairs keep the entire system functioning smoothly.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates