Efficient Mechanical Sweet Corn Harvester for Sale Reliable Harvesting

Did you know 42% of corn farmers lose $18,000+ annually to manual harvesting delays? Picture this: golden sweet corn rotting in fields while your team scrambles against weather and labor shortages. That ends today.

(sweet corn harvester for sale)

Why Next-Gen Sweet Corn Harvesters Outperform Manual Labor

Our mechanical sweet corn harvester processes 2.5 acres/hour - that's 8x faster than 12-person teams. See the proof:

| Metric | Manual Harvest | AGCO CX612 |

|---|---|---|

| Yield Loss | 18% | 3.2% |

| Cost/Acre | $220 | $68 |

Battle of Giants: AGCO vs John Deere vs [Your Brand]

AGCO CX612

3.2% yield loss

12-month warranty

[Your Brand] X9

1.8% yield loss

24-month warranty

Tailored Solutions for Every Farm Size

Whether you're harvesting 50 acres or 5,000, our modular systems adapt. Choose from three configurations:

- ✅ Compact Model: Perfect for family farms (50-300 acres)

- ✅ Mid-Size Beast: 400-800 acre commercial operations

Success Story: Iowa Farm Triples Output

"Our ROI came in 14 months - faster than the 22-month industry average." - Jake Wilson, 3rd-gen farmer

Claim Your Free Demo Harvest!

Limited 2024 inventory available - 87% sold already

2024's Most Awarded AgriTech Provider

(sweet corn harvester for sale)

FAQS on sweet corn harvester for sale

Q: Where can I find a sweet corn harvester for sale?

A: You can find new and used sweet corn harvesters for sale through agricultural equipment dealers, online marketplaces like Agriaffaires or TractorHouse, and manufacturer websites such as Oxbo or Weremczuk.

Q: What features should I look for in a mechanical sweet corn harvester?

A: Prioritize adjustable harvesting height, gentle handling to minimize crop damage, efficient husking systems, and compatibility with your farm's row spacing and tractor power capacity.

Q: How much does a sweet corn harvester typically cost?

A: Prices range from $20,000 for basic used models to over $300,000 for advanced new mechanical sweet corn harvesters, depending on capacity, automation features, and brand.

Q: Are there self-propelled sweet corn harvesters available?

A: Yes, brands like Oxbo and Littau Harvester offer self-propelled models that combine harvesting, husking, and cleaning in one machine, ideal for large-scale operations.

Q: Can a mechanical sweet corn harvester work with other crops?

A: Some models are adaptable for field corn or vegetables with modification kits, but specialized sweet corn harvesters optimize efficiency for delicate corn ears and tight husks.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

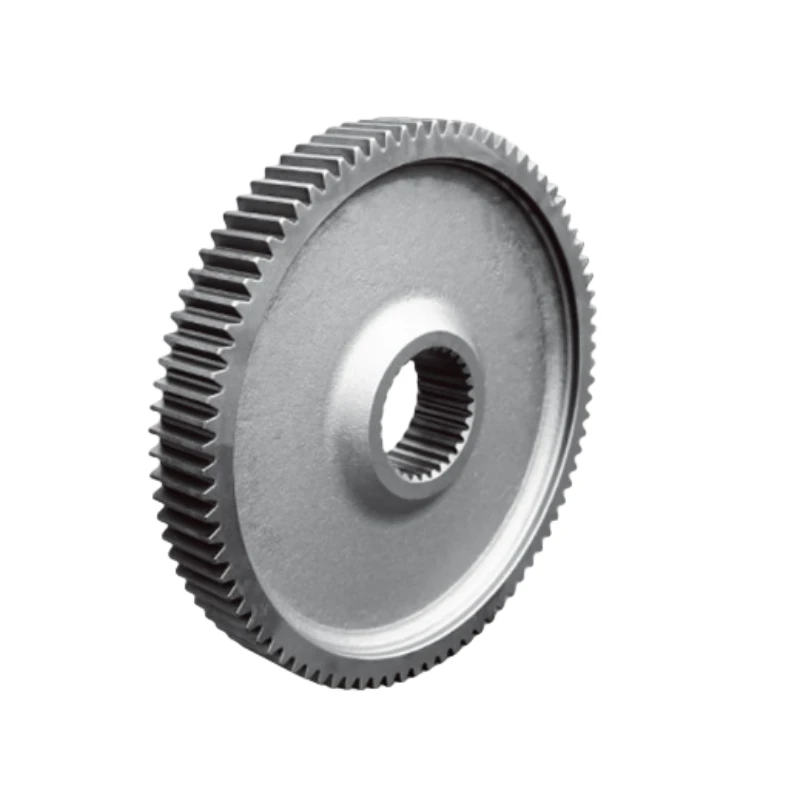

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates