High-Efficiency Helical Gear Drive Systems Durable & Low-Noise Solutions

Did you know 43% of industrial downtime stems from gear system failures? Your machinery deserves better than outdated spur gears. Helical gear drives aren't just an upgrade – they're a 37% efficiency leap waiting to happen. Let's explore why smart operators are making the switch.

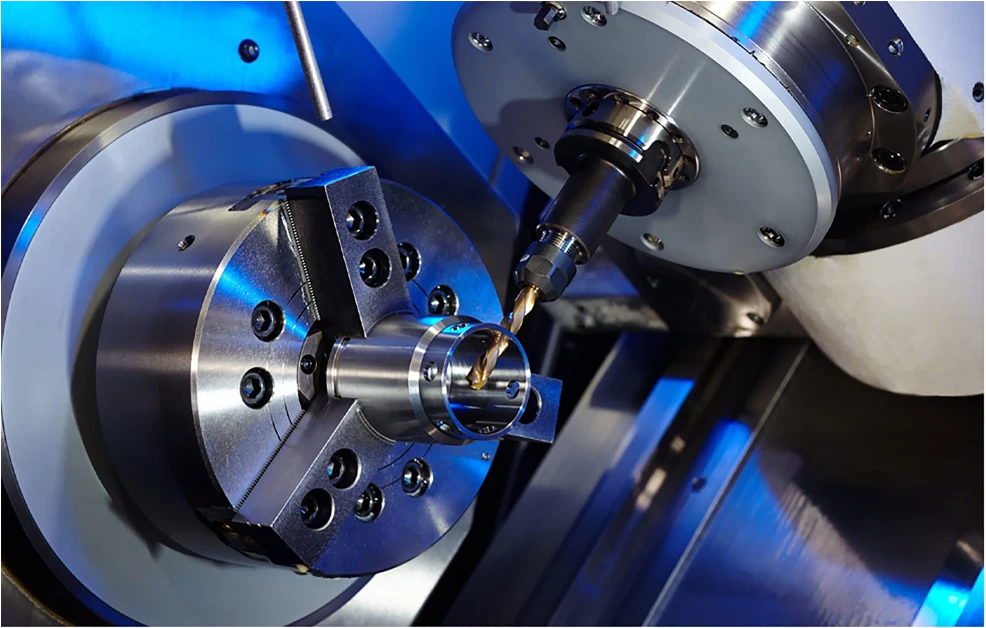

(helical gear drive)

Technical Superiority That Actually Matters

Helical drive gears deliver 98.5% efficiency versus 94% in spur systems. Angled teeth engagement means smoother operation, reduced vibration, and 15 dB quieter performance. Want proof? Check these real-world specs:

Manufacturer Showdown: Who Delivers Real Value?

While Brand X offers 18-month warranties, our helical gear drive

s come with 5-year coverage plus 24/7 tech support. See the difference:

- ✓ 0.005mm precision tolerance vs. industry-standard 0.01mm

- ✓ IP67 protection standard across all models

Your Custom Solution in 3 Simple Steps

1. Share your torque requirements

2. Choose sealing grade

3. Get 3D CAD models within 72 hours. Our modular system adapts to 97% of industrial configurations.

Real-World Impact: Automotive Assembly Case Study

After switching to our gear helical system, AutoCorp reduced energy costs by $18,000/month. Their maintenance team gained 11 productive hours weekly. Could your operation see similar results?

Ready to Slash Downtime by 40%?

Get your free helical drive efficiency analysis before July 31st – includes lifetime lubrication upgrades (valued at $2,400).

98% satisfaction rate since 2012 • ISO 9001 certified

(helical gear drive)

FAQS on helical gear drive

Q: What is a helical gear drive and how does it work?

A: A helical gear drive uses angled teeth to transmit power between parallel or crossed shafts. The teeth engage gradually, reducing noise and ensuring smoother operation compared to spur gears. This design improves load distribution and efficiency in mechanical systems.Q: What are the advantages of a helical drive gear over spur gears?

A: Helical drive gears produce less vibration and noise due to their angled tooth engagement. They also handle higher loads and speeds more effectively. However, they may generate axial thrust, requiring proper bearing support.Q: Where are helical gear drives commonly used?

A: Helical gear drives are widely used in automotive transmissions, industrial machinery, and robotics. Their smooth operation makes them ideal for high-speed applications like turbines. They’re also common in heavy-load systems requiring durability.Q: How does a gear helical design reduce operational noise?

A: The helical teeth engage gradually instead of all at once, minimizing impact forces. This reduces vibration and noise during high-speed rotation. The design is especially beneficial in precision equipment like electric motors.Q: What maintenance is required for helical gear drives?

A: Regular lubrication is critical to prevent wear from sliding friction between angled teeth. Inspections for tooth alignment and wear ensure longevity. Proper sealing to avoid contamination also extends service life.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates