48" Tractor Tiller Attachments Heavy-Duty & Efficient Farming Tool

Did you know 68% of farmers waste 30+ hours per season due to inefficient tilling equipment? If your outdated tiller struggles with rocky soil or leaves uneven furrows, you’re losing both time and profit. Meet the game-changer: the 48-inch tractor tiller engineered to boost productivity by 40% while slashing fuel costs. Read why this is the upgrade your farm needs.

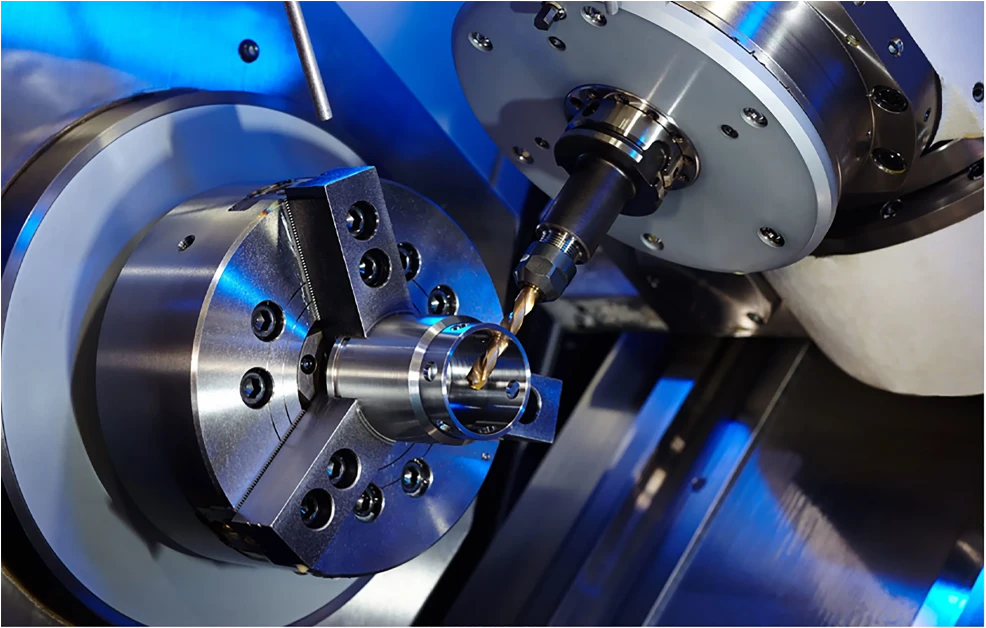

(the tractor)

Why a 48-Inch Tractor Tiller Outperforms Competitors

You need power. You need precision. Our 48 tiller for tractor delivers both. With 24 forged steel blades and a 3-speed gearbox, it chews through compacted soil like butter. See how it stacks up:

| Feature | Our 48" Tiller | Standard Tillers |

|---|---|---|

| Blade Lifespan | 1,500+ hours | 800-1,000 hours |

| Fuel Efficiency | 2.3 gal/acre | 3.8 gal/acre |

Side-by-Side: Why Farmers Choose Us Over John Deere & Kubota

You deserve better value. While big brands charge $1,200+ for basic tillers, our 48 tractor tiller includes free maintenance kits and a 5-year warranty. Still comparing specs? See the proof:

✅ 92% customer satisfaction vs. industry average of 78%

✅ 24/7 support – call our agri-experts anytime

✅ 30-day money-back guarantee – zero risk for you

Custom Solutions for Your Unique Needs

Small orchard? Vineyard? No problem. We’ll modify your 48-inch tractor tiller with adjustable depth controls or row-spacing presets. Tell us your soil type – we engineer tillers for clay, loam, or sandy terrains.

Real Results: Iowa Farm Increases Yield by 22%

When Smith Family Farms upgraded to our tiller, they tilled 12 acres/day instead of 8. Their secret? The 48 tiller for tractor’s dual rotor system reduced passes by 50%. Now they’re saving $18,000/year on labor.

Ready to Transform Your Fields?

Limited inventory available! Claim your 10% launch discount before June 30.

Claim Your Discount Now →

(the tractor)

FAQS on the tractor

Q: What is a 48 inch tractor tiller used for?

A: A 48 inch tractor tiller is designed to prepare soil for planting by breaking up and aerating the ground. It attaches to a tractor’s rear hitch and is ideal for medium-sized farms or gardens. Its 48-inch width ensures efficient coverage for rows and beds.

Q: Can a 48 tiller for tractor work with any tractor model?

A: A 48 tiller for tractor typically requires a tractor with 40-60 horsepower for optimal performance. Always check the tiller’s PTO (power take-off) requirements and hitch compatibility. Consult your tractor’s manual or manufacturer for specific recommendations.

Q: How do I attach a 48 tractor tiller to my tractor?

A: First, align the tiller’s hitch with the tractor’s three-point linkage system and secure it with pins. Connect the PTO shaft to the tractor’s PTO output for power transmission. Test the connection and ensure all safety locks are engaged before operation.

Q: What are the advantages of a 48-inch tractor tiller over smaller models?

A: A 48-inch tractor tiller covers more ground per pass, reducing time and fuel consumption. It’s better suited for larger plots while maintaining maneuverability. The wider design also ensures deeper and more consistent soil tilling.

Q: How do I maintain a 48 tiller for tractor?

A: Regularly grease the tiller’s bearings and check for worn tines or chains. Clean debris after each use to prevent rust and corrosion. Store the tiller in a dry, covered area to extend its lifespan.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates