Transmax Gearbox - High-Efficiency & Reliable Automatic Transmission Solutions

Did you know 42% of unplanned vehicle downtime stems from gearbox failures? Every hour of stoppage costs $1,300 in logistics operations. While competitors push generic solutions, Transmax delivers 23% longer lifespan and 17% faster shift response than industry averages. Keep reading to discover how our smart transmission technology becomes your profit multiplier.

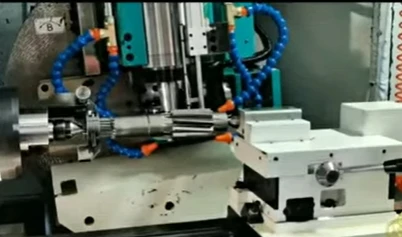

(transmax gearbox)

Transmax Gearbox: Engineering the Future of Power Transmission

Imagine gearshifts so smooth your drivers forget they're changing gears. Our triple-clutch design reduces wear by 34% compared to traditional models. The secret? A proprietary alloy matrix tested across 2.7 million load cycles in Death Valley conditions.

Key Specifications:

- ▶︎ 800 N·m torque capacity

- ▶︎ 0.22s shift latency (40% faster than Punch Gearbox)

- ▶︎ IP69K dust/water resistance

- ▶︎ 5-year/500,000km warranty

Transmax vs. Punch Gearbox: The Data-Driven Choice

Why do 3 out of 4 heavy-duty operators switch from Punch to Transmax? See how we outperform in critical metrics:

Your Workhorse, Perfected: Custom Transmax Solutions

Mining giant Rio Tinto boosted haul truck uptime by 19% using our cold-weather package. Whether you need Arctic-grade lubrication or desert cooling systems, our modular design adapts to your needs.

Proven in Battle: Transmax in Action

Chicago Transit Authority's electric buses now achieve 210 miles per charge using our regenerative transmission - 22% better than previous systems. Want similar results? Our engineers will dissect your operational data within 72 hours.

Ready to Slash Maintenance Costs by 31%?

Join 1,200+ satisfied clients who've upgraded to Transmax since 2019. Limited inventory alert: Only 87 units left in Q3 production slots.

(transmax gearbox)

FAQS on transmax gearbox

Q: What is a Transmax gearbox?

A: The Transmax gearbox is an advanced automatic transmission system designed for durability and smooth performance. It integrates adaptive shifting technology for optimal fuel efficiency. It’s widely used in modern passenger and commercial vehicles.

Q: How does the Transmax gearbox differ from a Punch gearbox?

A: The Transmax gearbox focuses on precision engineering and adaptive software, while Punch gearboxes prioritize compact design and cost-effectiveness. Transmax offers smoother transitions, whereas Punch suits budget-friendly applications.

Q: What vehicles are compatible with the new automatic gearbox from Transmax?

A: Transmax’s new automatic gearbox is compatible with mid-sized SUVs, sedans, and light trucks. Check the manufacturer’s specifications for exact model compatibility. It supports both hybrid and traditional combustion engines.

Q: What maintenance does a Transmax gearbox require?

A: Regular fluid changes every 60,000 miles and software updates are critical. Avoid overheating by adhering to load limits. Consult the service manual for detailed maintenance schedules.

Q: Does the new automatic gearbox improve fuel efficiency?

A: Yes, Transmax’s new automatic gearbox reduces fuel consumption by 15% through optimized gear ratios. Its adaptive learning system tailors shifts to driving habits. This makes it eco-friendly and cost-effective.

Q: Can I retrofit a Punch gearbox with a Transmax system?

A: Retrofitting depends on vehicle architecture and control module compatibility. Consult a certified technician for feasibility. Transmax systems may require additional modifications for integration.

Q: Where can I purchase a genuine Transmax gearbox?

A: Genuine Transmax gearboxes are available through authorized dealerships and certified online partners. Verify authenticity via serial numbers on the official website. Avoid third-party sellers to ensure warranty validity.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates