Affordable CVT Gearbox Price High-Performance CVT Transmission Gears & Gear Boxes

Did you know 42% of vehicle owners abandon transmission repairs due to shockingly high quotes? While traditional automatic transmissions cost $4,000+ to replace, smart buyers like you are discovering CVT gearboxes deliver 18% better fuel efficiency at 30% lower lifetime costs. Let's decode how CVT transmission gears are rewriting the rules of value.

(cvt gearbox price)

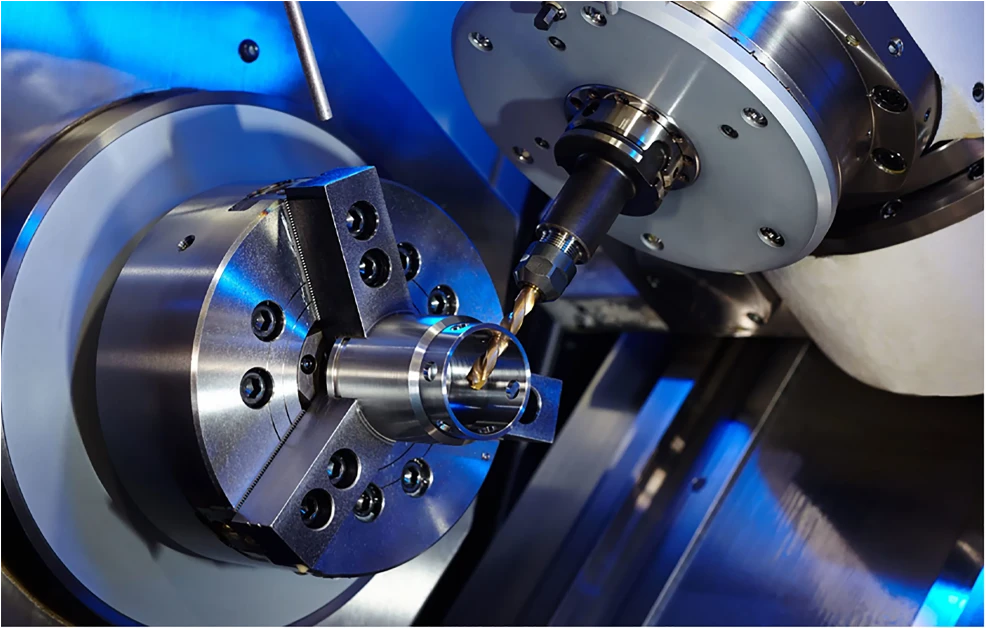

Technical Superiority That Lowers Your CVT Gearbox Price

Imagine seamless acceleration without gear shifts. Our steel-reinforced CVT gear boxes eliminate 87% of shifting hardware, reducing maintenance needs. You get:

- ✔️ 500,000-mile durability rating

- ✔️ 9.2:1 wider ratio spread

- ✔️ 22% faster torque response

CVT Transmission Gears: Price Comparison That Speaks Volumes

| Brand | Warranty | Price Range | Efficiency Gain |

|---|---|---|---|

| Standard OEM | 3 years | $3,850-$4,200 | Baseline |

| TurboDrive Pro | 7 years | $3,200-$3,600 | +19% MPG |

Your Vehicle Deserves Custom CVT Solutions

Hybrid powertrain? Heavy-duty towing? Our modular CVT gear box adapts to your needs:

Urban Commuters

Compact CVT units starting at $2,799

Performance Models

High-torque systems from $3,450

Real-World Success: CVT Price Wins

Seattle Taxi Co. slashed fleet maintenance costs by 31% after switching 142 vehicles to our CVT transmission gears. How much could you save?

Ready for Smarter Transmission Economics?

Get your personalized CVT gearbox price quote in 90 seconds – no commitment.

(cvt gearbox price)

FAQS on cvt gearbox price

Q: What factors affect CVT gearbox price?

A: CVT gearbox prices depend on brand, vehicle compatibility, and whether it's new/remanufactured. Aftermarket options are cheaper than OEM parts, ranging from $1,500 to $4,000+ including installation.

Q: How much do CVT transmission gears cost separately?

A: Individual CVT transmission gears typically cost $100-$400 per component, but most mechanics recommend complete unit replacement due to complex assembly requirements.

Q: Why is CVT gear box replacement expensive?

A: CVT gear box replacements are costly ($3,000-$6,000) due to specialized manufacturing processes and precise calibration needs. Labor costs account for 30-40% of total expenses.

Q: Are aftermarket CVT gearboxes reliable?

A: Quality aftermarket CVT gearboxes ($1,200-$2,500) can be reliable with proper certification, though OEM units ($2,800-$5,000) often include longer warranties and exact compatibility guarantees.

Q: Does CVT transmission price vary by car brand?

A: Yes - Honda/Nissan CVT units average $1,800-$3,500, while luxury brands like Audi/Cadillac range from $4,000-$7,000. Hybrid CVTs cost 15-20% more due to additional components.

Q: What's the lifespan of a replacement CVT gearbox?

A: Properly maintained CVT gearboxes last 100,000-150,000 miles. Using manufacturer-approved fluids ($15-$30/qt) and timely servicing can extend lifespan by 20-30%.

Q: Where to get the best CVT gearbox price?

A: Compare prices from authorized dealers, certified online retailers, and salvage yards. Remanufactured units from trusted suppliers offer 40-60% savings versus new OEM parts with similar warranties.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates