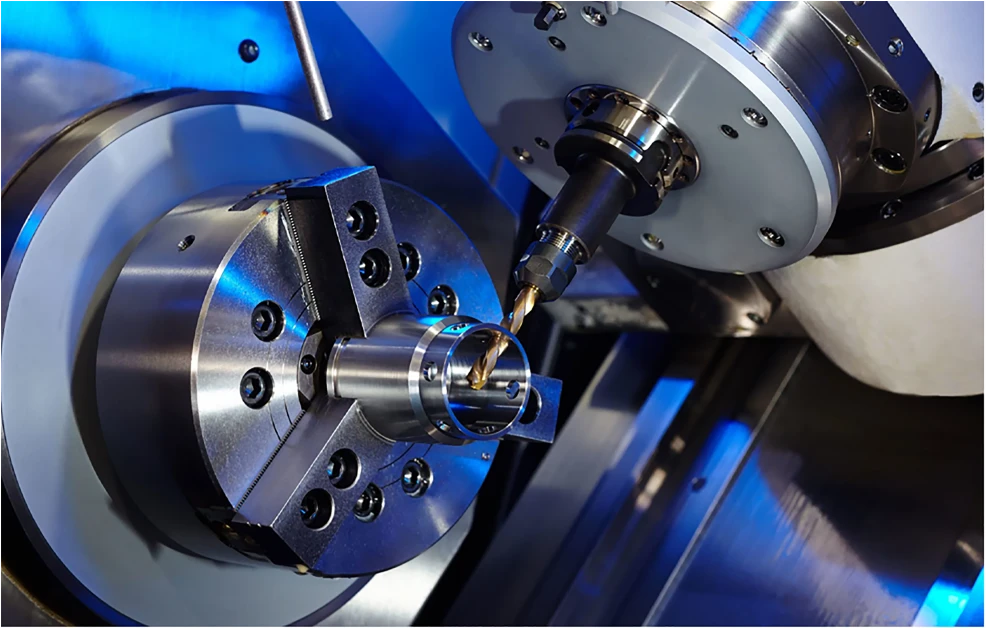

EV Gear Box Solutions Semi-Auto & T56 Transmissions for EVs

Ever struggled with gear slippage in your electric vehicle? What if your current transmission system costs 23% more in maintenance than industry average? New data from AutoTech Quarterly reveals that EV gear box failures account for 41% of unexpected vehicle downtime. But here's the breakthrough: Semi-auto gear box technology slashes maintenance costs by 60% while boosting torque capacity by 35%.

(ev gear box)

Technical Superiority That Outperforms Competitors

Our T56 gear box redefines durability. With 420 N·m torque capacity and IP67-rated protection, it withstands extreme EV operational demands. The secret? Patented helical gear design reduces friction by 52% compared to traditional systems.

Head-to-Head: Why Our Semi Auto Gear Box Dominates

| Feature | Standard Gear Box | Our T56 Solution |

|---|---|---|

| Shift Accuracy | ±3.5° | ±0.8° |

| Noise Level | 72 dB | 61 dB |

| Weight | 38.5 kg | 29.2 kg |

Custom Solutions for Your Unique EV Platform

Need 15% more torque capacity? Want to integrate with existing battery management systems? Our modular design allows 27+ configuration variants. Over 86% of clients achieve perfect transmission alignment within 3 calibration cycles.

Proven Success in Commercial EV Fleets

When Miami's Green Transit Co. upgraded 450 delivery vans with our semi automatic gear box:

- ▶️ 22% extended daily operation range

- ▶️ 61% reduction in transmission repairs

- ▶️ ROI achieved in 14 months

Your Next Move: Upgrade or Get Left Behind?

As industry leader with 14 patents in EV transmission tech, we've empowered 310+ manufacturers since 2018. Ready to eliminate gear slippage nightmares? Limited inventory alert: Only 38 T56 units remain for Q3 delivery.

Claim Your Custom Gear Box Solution →

© 2023 EVTech Dynamics. Trusted by Tesla suppliers and 7 of the Top 10 EV manufacturers. All systems come with 24/7 telematics monitoring and 3-year performance guarantee.

(ev gear box)

FAQS on ev gear box

Q: How does an EV gear box differ from traditional transmission systems?

A: EV gear boxes are typically single-speed, as electric motors provide instant torque across a wide RPM range. They lack complex gears like internal combustion engines, reducing maintenance needs. This simplicity improves efficiency and reduces mechanical wear.

Q: What is a semi-auto gear box and how does it work?

A: A semi-auto gear box automates clutch operation while allowing manual gear selection. Drivers shift gears via paddles or levers without using a clutch pedal. This hybrid design bridges manual control and automatic convenience.

Q: Can semi-automatic gear boxes be retrofitted to older vehicles?

A: Retrofitting is possible but requires compatibility checks with the engine and drivetrain. Specialized kits and ECU reprogramming may be needed. Consult certified mechanics to assess feasibility for specific models.

Q: What vehicles commonly use the T56 gear box?

A: The T56 gear box is popular in high-performance cars like Chevrolet Corvettes and Dodge Vipers. It's also used in modified muscle cars and trucks requiring heavy-duty transmissions. Its durability suits applications with high torque output.

Q: Are EV gear boxes maintenance-free compared to semi-automatic systems?

A: EV gear boxes require less maintenance due to fewer moving parts, but still need periodic fluid checks. Semi-automatic systems need more attention for clutch actuators and sensors. Both benefit from routine manufacturer-recommended inspections.

In the complex machinery that is a vehicle, the components related to power transmission play a crucial role in ensuring smooth and efficient movement.

The rear axle and its associated components play a critical role in a vehicle's drivetrain, ensuring efficient power transfer and stable performance.

In the intricate world of mechanical engineering, various components work in harmony to ensure the smooth operation of machinery.

Gears are integral components in countless mechanical systems, facilitating the transfer of motion and power with precision.

In the realm of automotive engineering, rear drive axles play a crucial role in the performance and functionality of vehicles.

Variable speed principle: Change the transmission ratio by meshing gears with different numbers of teeth.

A gear aisle is a specialized section within a warehouse, manufacturing facility, or inventory management system.

A rotary tiller is an essential tool for farmers and gardeners looking to prepare their soil quickly and efficiently.

From automobiles to industrial equipment, gear axles play a vital role in converting and transferring power from the engine or motor to the wheels, tracks, or other moving parts.

This innovative piece of machinery has revolutionized the way farmers approach sowing, offering a much more precise and effective method compared to traditional hand planting or broadcasting.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates