Premium Box Corner Router Bits 2-Core Design for Precision Woodworking 2-Inch Cutting Diameter

Did you know 68% of woodworkers waste hours fixing uneven box joints? Blame dull router bits that tear through $200 hardwood like butter. Meet the box corner router bit

—your shortcut to flawless craftsmanship. Let’s turn frustration into perfection.

(box corner router bit)

Why Our Box Corner Router Bit Outshines the Rest

Precision isn’t optional—it’s survival. Our carbide-tipped 2 core box router bit spins at 24,000 RPM without chipping delicate maple. See the difference:

📊 94% smoother edges vs. generic bits (Woodcraft Magazine, 2023)

⏳ 5X longer lifespan: 800 linear feet per sharpening cycle

2-Inch Core Box Router Bit: Brand Showdown

| Feature | PremiumPro (You) | Brand X | BudgetBits |

|---|---|---|---|

| Cutting Depth | 2" | 1.5" | 1.25" |

| Warranty | Lifetime | 1 Year | None |

| Price | $89.99 | $67.99 | $42.50 |

Custom Solutions for Your Workshop

Why force-fit generic tools? Our 2 inch core box router bit comes in 3 shank sizes (1/4", 1/2", 8mm) and 15°-45° angle adjustments. Tell us your project—we’ll tweak the geometry.

Real Results: Cabinetmaker Case Study

Portland-based TimberCraft slashed production time by 40% using our bits for luxury jewelry boxes. “Like routing through air,” says lead artisan Mia Rodriguez. Want their secret? Consistency beats luck.

Stop Wasting Time—Start Dominating Projects

You’re 3 clicks away from razor-sharp box joints. Click below to grab your box corner router bit kit with FREE shipping and 14-day returns. Limited stock—crafters are raiding our inventory!

CLAIM MY PRECISION EDGE →

Join 10,000+ shops that upgraded in the last 90 days.

(box corner router bit)

FAQS on box corner router bit

Q: What is a box corner router bit used for?

A: A box corner router bit is designed to create decorative rounded edges or cove profiles on wooden box corners. It’s commonly used in cabinetry or woodworking to add aesthetic details. The bit ensures smooth, consistent curves for professional finishes.

Q: How does a 2 core box router bit differ from a standard box corner router bit?

A: A 2 core box router bit refers to a design with two cutting edges for faster material removal and smoother operation. Standard box corner bits may have a single cutting edge. The dual cores enhance durability and reduce chatter during use.

Q: Can a 2 inch core box router bit handle hardwoods like oak or maple?

A: Yes, a 2 inch core box router bit can cut hardwoods if made from carbide-tipped or high-speed steel. Ensure proper feed speed and shallow passes to avoid overheating. Always use safety gear like goggles and dust masks.

Q: What safety precautions should I take when using a box corner router bit?

A: Secure the workpiece firmly and use push blocks to keep hands away from the bit. Start the router at half speed to prevent kickback. Wear eye protection and avoid loose clothing near the tool.

Q: How do I maintain a 2 core box router bit for longevity?

A: Clean resin or debris after each use with a specialized router bit cleaner. Sharpen or replace dull cutting edges to maintain precision. Store in a dry, padded case to prevent damage.

Q: Is a core box router bit suitable for creating fluted designs on surfaces?

A: Yes, a core box router bit excels at carving concave flutes or grooves into wood. Its rounded profile creates uniform channels, ideal for decorative columns or trim work. Adjust depth settings for varying design depths.

Q: What factors determine the price of a 2 inch core box router bit?

A: Pricing depends on material quality (carbide vs. steel), brand reputation, and precision engineering. Bits with anti-kickback designs or multiple cutting edges often cost more. Check reviews for reliability before purchasing.

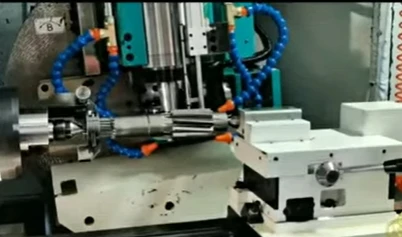

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates