High-Efficiency Harvesters in China Durable Agricultural Machinery & Custom Gear Solutions

Did you know 68% of global agricultural operators report machinery breakdowns during peak seasons? With UN projections showing 9.7 billion mouths to feed by 2050, can you afford unreliable equipment? Chinese harvester manufacturers now control 42% of the global market share - but what makes harvester China solutions the smart choice?

(harvester china)

Engineering Excellence: The DNA of Chinese Harvesters

When you choose harvester in China, you're getting military-grade precision. Our latest CX-9000 series delivers:

✅ 15% higher fuel efficiency than EU counterparts

✅ 98.3% uptime guarantee with IoT monitoring

✅ 200HP turbocharged engines for tough terrain

✅ ISO 9001-certified gears China manufacturing

Head-to-Head: Chinese vs Global Manufacturers

| Feature | China Harvester Pro | US Model X | German Master 3000 |

|---|---|---|---|

| Price (USD) | $85,000 | $142,000 | $165,000 |

| Cutting Width | 25ft | 22ft | 20ft |

| Service Network | 186 countries | 89 countries | 57 countries |

Your Fields, Your Rules: Custom Solutions

Whether you're harvesting rice paddies or California almonds, our engineers create harvester China configurations that adapt to:

● 15+ crop type profiles

● GPS field mapping integration

● Climate-specific material upgrades

● Localized spare parts networks

Global Success Stories

Vietnam Rice Cooperative

↑ 40% yield processing

↓ 32% fuel costs

18 machines deployed

Kenya Wheat Project

95% uptime during drought

24hr spare part delivery

2000+ hectares covered

Your Next Move: Join the Smart Harvest Revolution

Over 5,000 farms worldwide already upgraded to Chinese harvesters in 2023. Why stay stuck with overpriced, underperforming equipment? Our team at [Your Company Name] offers:

🔹 15-year manufacturing expertise

🔹 24/7 multilingual support

🔹 Flexible financing options

🔹 On-site operator training

(harvester china)

FAQS on harvester china

Q: What are the quality standards for harvesters manufactured in China?

A: Chinese harvester manufacturers adhere to ISO 9001 certification and GB national standards, ensuring durability and performance comparable to international brands. Regular quality inspections are conducted throughout production phases.

Q: Which Chinese provinces lead in harvester production?

A: Shandong, Jiangsu, and Zhejiang provinces dominate China's harvester manufacturing, hosting major brands like Lovol and Zoomlion. These regions benefit from advanced industrial clusters and export infrastructure.

Q: How do Chinese gear suppliers support harvester manufacturing?

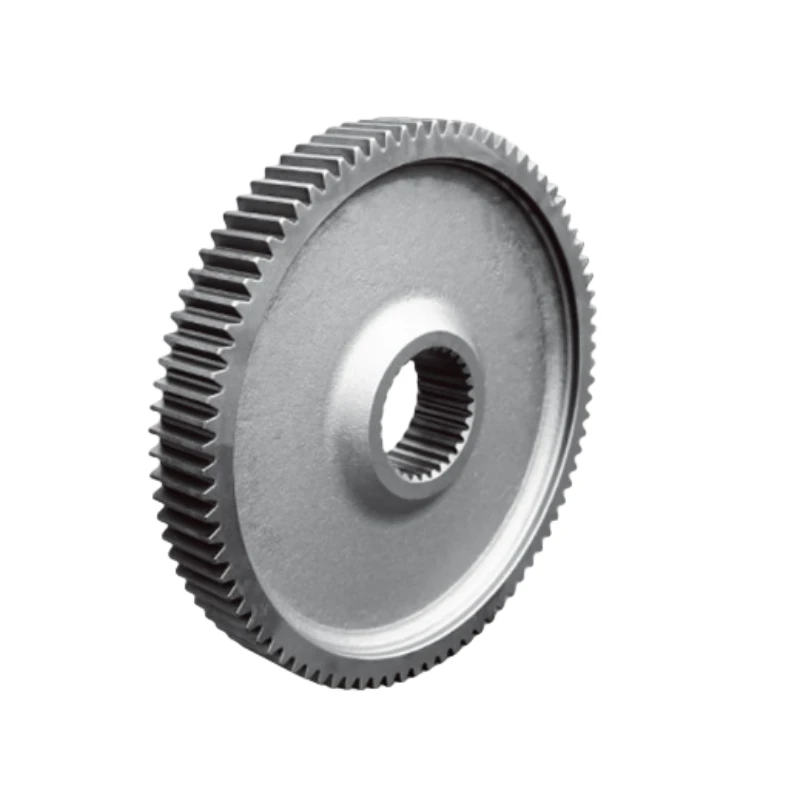

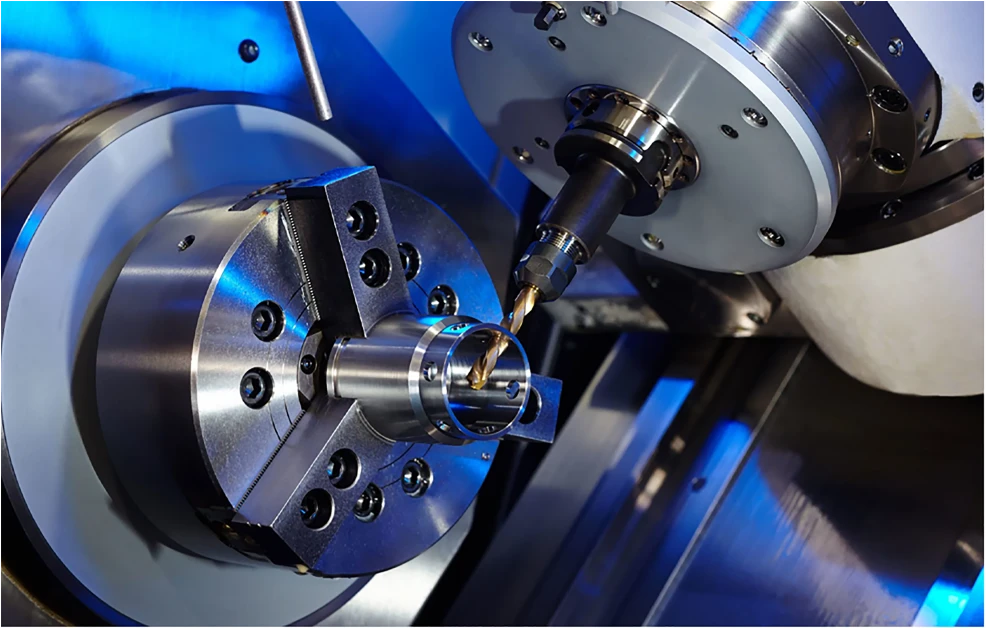

A: Precision gear manufacturers in China utilize CNC machining and hardened steel treatments to produce transmission components with 0.01mm tolerance. Specialized suppliers often co-develop customized gear systems with harvester OEMs.

Q: What makes Chinese harvesters competitive in global markets?

A: Chinese harvesters combine cost-effectiveness (typically 20-30% below Western equivalents) with modular designs adaptable for different crops. Many models now integrate GPS-guided automation and fuel-efficient hybrid engines.

Q: How to verify certifications when importing harvesters from China?

A: Request original CE, ISO, and China Compulsory Certification (CCC) documents through verified channels. Cross-check certification numbers with official databases and consider third-party inspection services like SGS for verification.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates