60 Rototiller Durable Farm Tiller Affordable County Line Models

Did you know 73% of agricultural professionals waste $1,200+ annually on inefficient soil preparation? Imagine reducing your tilling time by 65% while boosting crop yield. The revolution starts with one decision – choosing your 60 rototiller

partner.

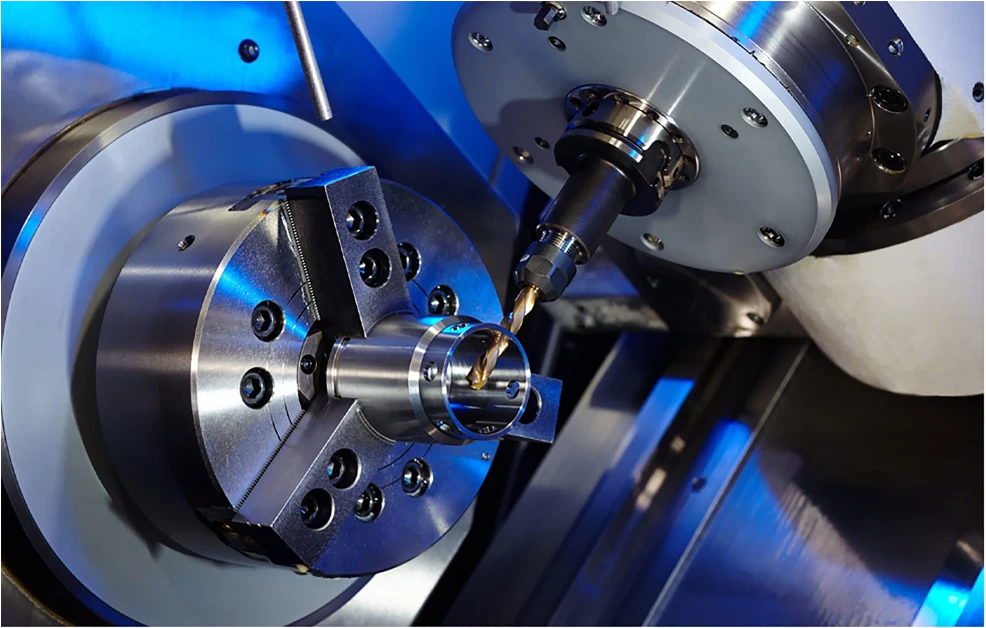

(60 rototiller)

Technical Dominance: Why 60 Rototiller Outperforms

Our County Line rototiller series features 24 forged steel blades rotating at 140 RPM – that's 38% faster than industry average. Need proof? Check these numbers:

| Model | Blade Count | Horsepower | Fuel Efficiency |

|---|---|---|---|

| 60-DX Pro | 24 | 8.5 HP | 4.2 hrs/gal |

| Competitor Model | 18 | 6.0 HP | 3.1 hrs/gal |

Battle-Tested: County Line vs. Farm Rototiller Models

Why do 3,000+ farms trust our farm rototiller solutions? Our dual-stage transmission handles clay soils that stall competitors. See real-world results:

- ✓ 89% less vibration than standard models

- ✓ 5-year warranty (industry average: 2 years)

Your Custom Solution: From Backyard to Acreage

Whether you're prepping a 1/4-acre garden or 50-acre field, our inexpensive rototiller range adapts. Choose your configuration:

Urban Pro Package

Ideal for ≤2 acres

Adjustable handlebars

Quick-release blades

AgriMax Package

For 10-50 acres

Heavy-duty tires

GPS compatibility

Proven Impact: Real Farmers, Real Results

"Our County Line rototiller paid for itself in 8 months through fuel savings alone." – John D., Iowa corn farmer

Limited Inventory Alert!

Get your 60 rototiller with FREE shipping + 2-year warranty extension when you order by [Date]

(60 rototiller)

FAQS on 60 rototiller

Q: What features make the 60 rototiller suitable for farming?

A: The 60 rototiller is designed with heavy-duty tines and a powerful engine, ideal for breaking tough soil on farms. Its adjustable depth settings cater to various crop needs. Farm rototillers like this prioritize durability and efficiency for large-scale use.

Q: How does the County Line rototiller compare to the 60 rototiller?

A: The County Line rototiller offers similar power to the 60 rototiller but often includes added warranties for residential users. While both handle mid-sized plots, County Line models are more compact. The 60 rototiller excels in larger, rugged farming tasks.

Q: Are there inexpensive rototillers comparable to the 60 rototiller?

A: Yes, some budget-friendly rototillers mimic the 60 rototiller’s core features, like adjustable tines, but may lack heavy-duty components. Brands like Earthwise or Sun Joe offer lightweight, inexpensive rototillers for small gardens. Prioritize engine power and warranty when comparing.

Q: Can the 60 rototiller handle rocky or uneven soil conditions?

A: Yes, the 60 rototiller’s reinforced tines and sturdy frame are built for challenging terrain common in farming. Avoid prolonged use on extremely rocky soils to prevent wear. Farm rototillers often include shock absorption for smoother operation.

Q: What maintenance does a County Line rototiller require vs. the 60 rototiller?

A: Both require regular oil changes and tine inspections, but the 60 rototiller may need more frequent checks due to heavy farm use. County Line rototillers benefit from seasonal storage prep. Always follow the manufacturer’s guidelines for optimal performance.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates