Forging

Blank forging area:

Metal plasticity is used to plastically deform the metal billet by applying an external force (such as impact force or pressure) to obtain a blank of the desired shape, size and properties. This plastic deformation will change the internal microstructure of the metal, allowing the grains to refine and align along the deformation direction, enhancing the mechanical properties of the metal.

Blank forging features:

For gears with small size and low accuracy requirements, forging blanks are often used. Using a die to apply pressure through forging equipment to form metal materials can improve material properties.

For gears with high precision and complex structure, use a casting blank, pour liquid metal into the mold cavity, and cool and solidify to obtain a gear blank with complex shape.

For gears with large batches and high strength requirements, die forging can be used to obtain a more accurate size and shape of the blank.

-

Tractor Gear Shaft

Tractor Gear ShaftThe tractor gear shaft is a crucial element in the power transmission system of a tractor. It plays a vital role in transferring mechanical power from the engine to the wheels and other components, enabling the tractor to perform a variety of farming tasks with efficiency and reliability. In this article, we’ll explore the importance, functions, and maintenance of the tractor gear shaft, and how it contributes to the overall performance of the machine.

-

Transmission Gear

Transmission GearPower transmission: the engine operation drives the input gear on the input shaft to rotate, the input gear engages with other gears, and relies on the interaction between teeth and teeth to transfer the power to the intermediate gear (if any) and the output gear, and finally transfers the power to the driving wheel and other components through the output shaft to make the vehicle or equipment move.

Variable speed principle: Change the transmission ratio by meshing gears with different numbers of teeth. For example, when the big gear drives the small gear, the speed of the small gear will be faster than the big gear, but the output torque will be smaller, to achieve growth and torque reduction; On the contrary, when the pinion drives the big gear, the speed of the big gear slows down, the torque increases, and the torque increases. In this way, transmission gears enable the vehicle or equipment to obtain the right speed and torque under different working conditions -

Transmission Gear

Transmission GearTransmission Gear are vital components in machinery, particularly in heavy-duty equipment such as tractors, harvesters, and construction machinery. These gears play a crucial role in transmitting power from the engine to the wheels, ensuring smooth and efficient operation. Designed for durability, Transmission Gear are made from high-quality materials like steel and alloy to withstand the immense stresses and high temperatures encountered during operation.

-

Tractor Active Gear Shaft

Tractor Active Gear ShaftThe tractor active gear shaft is a critical component in the power transmission system of a tractor, responsible for transferring rotational power from the engine or transmission to other parts of the tractor. By efficiently distributing torque and enabling smooth gear shifts, the active gear shaft plays a vital role in enhancing the performance and versatility of the tractor, making it essential for a wide range of agricultural tasks. In this article, we’ll explore the function, benefits, and maintenance of the tractor active gear shaft.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

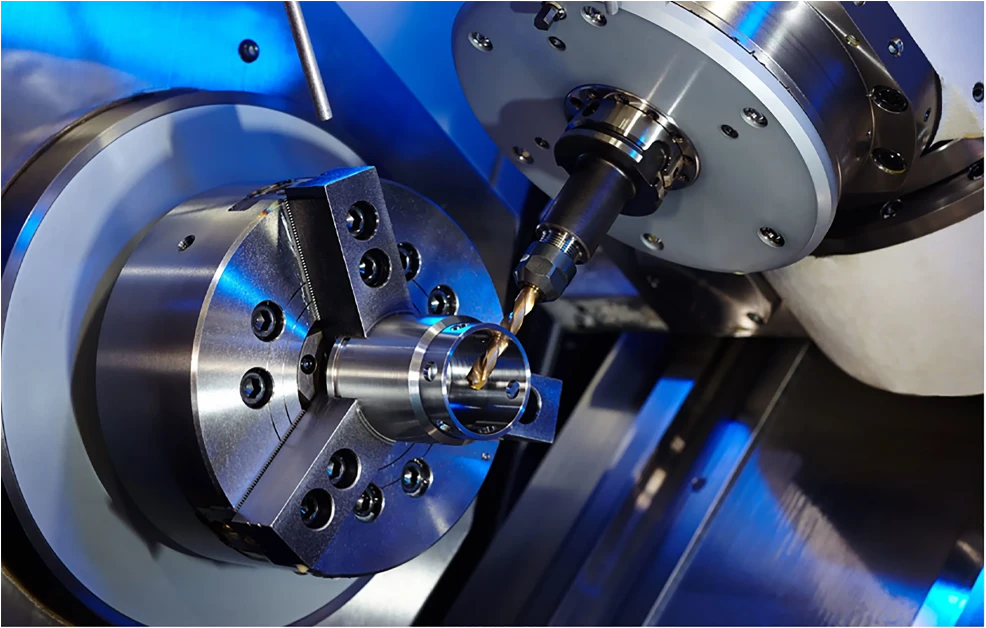

High-Strength Forging – Precision and Durability Redefined

Engineered with advanced forging techniques, our components deliver superior strength, enhanced durability, and exceptional precision for the most demanding applications.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates