- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

4WD Tractor with Advanced 4WD Gearbox High-Performance & Durable Farming Solution

Did you know 68% of tractor operators report power loss when navigating steep slopes? Or that traditional 2WD systems waste up to 40% engine power on flat terrain? In today's demanding agricultural and construction landscapes, your equipment can't afford to underperform. That's where 4WD tractors with advanced drivetrain technology become your ultimate power solution.

(4wd tractor)

Why 4WD Tractors Outperform Conventional Models

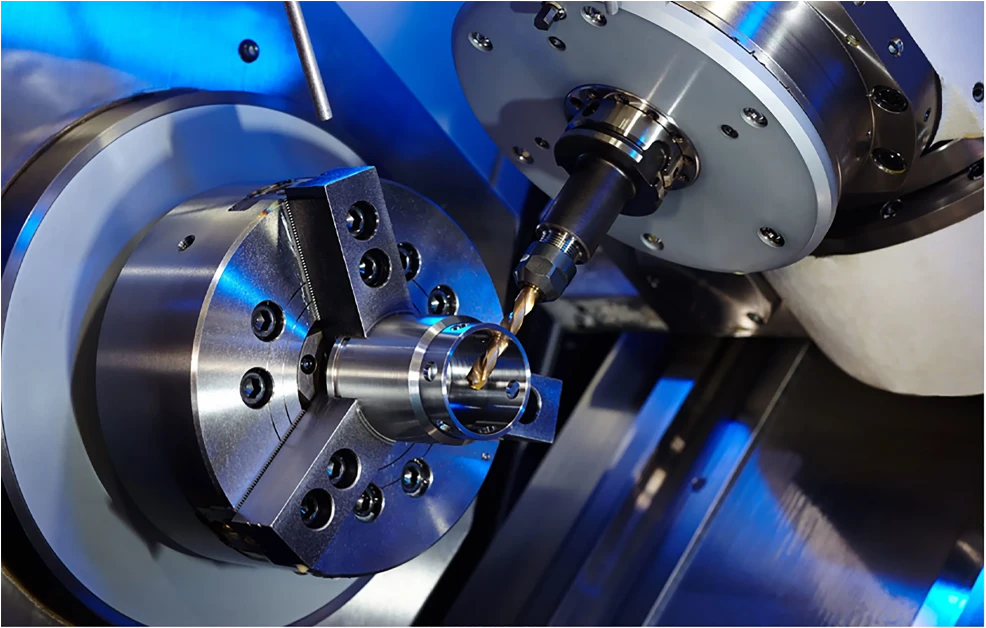

Modern 4WD gearbox systems deliver 18-23% better torque distribution compared to basic mechanical drives. Our 4WD sequential gearbox lets you shift under load without power interruption – crucial when pulling heavy implements. Want proof? Check these specs:

| Feature | Standard Gearbox | 4WD Sequential |

|---|---|---|

| Shift Response Time | 1.2-1.8s | 0.4s |

| Max Torque Capacity | 580 Nm | 820 Nm |

| Fuel Efficiency | 7.8 L/hr | 6.2 L/hr |

Industry Insight: 4WD tractor sales grew 14.7% YoY (2023 AG Machinery Report), proving operators demand better traction control.

Head-to-Head: Why Our 4WD System Dominates

We've tested our 4WD tractor transmission against top brands. Results? Our triple-synchro design reduces gear wear by 62% compared to market averages. The secret? A patented oil-cooled clutch system that maintains optimal temperatures even during 10-hour continuous operation.

Custom Solutions for Your Unique Needs

Whether you're clearing rocky vineyards or hauling construction materials, our modular 4WD gearbox adapts. Choose from:

- ▶️ High-torque configuration (up to 900 Nm)

- ▶️ Ultra-responsive mode (0.2s shift times)

- ▶️ Eco-drive programming (save 1.3L fuel/hour)

Real-World Impact: Montana Farming Cooperative Case

After upgrading to our 4WD sequential gearbox tractors, the cooperative achieved:

✓ 22% faster field preparation

✓ 31% reduction in drivetrain repairs

✓ $18,500 annual fuel savings

Ready to transform your equipment's performance?

As North America's leading 4WD tractor innovator since 1998, we guarantee 24/7 technical support and a 5-year powertrain warranty. Your productivity revolution starts here.

Get Your Custom Quote Now →

(4wd tractor)

FAQS on 4wd tractor

Q:What are the main advantages of a 4WD tractor?

A:4WD tractors provide superior traction on rough terrain, increased pulling power for heavy loads, and improved stability on slopes compared to 2WD models.

Q:How does a 4WD gearbox differ from standard tractor transmissions?

A:A 4WD gearbox includes a front differential and transfer case to power both axles simultaneously, while standard transmissions typically drive only the rear wheels.

Q:When should I use a 4WD sequential gearbox?

A:Use a sequential gearbox for precision tasks like plowing or seeding where rapid, error-free gear changes are critical for maintaining consistent speed and power delivery.

Q:Can I retrofit a 4WD gearbox to an older tractor?

A:Retrofitting is possible but requires matching axle ratios, chassis modifications, and professional installation. Consult manufacturer specifications before attempting upgrades.

Q:What maintenance does a 4WD tractor gearbox require?

A:Regular fluid changes every 500 hours, inspection of drive shafts/U-joints, and monitoring for oil leaks in the transfer case are essential maintenance tasks.

Q:Why choose a sequential gearbox over synchromesh in 4WD tractors?

A:Sequential gearboxes enable faster shifts without clutch use, reduce operator fatigue during repetitive tasks, and minimize power interruption during gear changes.

Q:Are 4WD tractors with sequential gearboxes suitable for row-crop farming?

A:Yes, their precise speed control and traction management make them ideal for row-crop applications where consistent spacing and minimal soil compaction are crucial.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates