Gear Guality Inspection

Gear quality inspection area:

Dimensional inspection area: Use measuring tools such as calipers, micrometers, coordinate measuring machines, etc. to measure the dimensional accuracy of gears to ensure that they meet design requirements.

Shape and position tolerance detection area: Use yaw meter, jitter, etc. to detect the shape and position tolerances such as circular jitter and cylindricity of gears to ensure the accuracy and stability of gear transmission.

Tooth shape accuracy detection area: use a gear measuring instrument to detect tooth shape accuracy indicators such as tooth shape error and tooth pitch deviation.

-

Tractor Gear Shaft

Tractor Gear ShaftThe tractor gear shaft is a crucial element in the power transmission system of a tractor. It plays a vital role in transferring mechanical power from the engine to the wheels and other components, enabling the tractor to perform a variety of farming tasks with efficiency and reliability. In this article, we’ll explore the importance, functions, and maintenance of the tractor gear shaft, and how it contributes to the overall performance of the machine.

-

Transmission Gear

Transmission GearPower transmission: the engine operation drives the input gear on the input shaft to rotate, the input gear engages with other gears, and relies on the interaction between teeth and teeth to transfer the power to the intermediate gear (if any) and the output gear, and finally transfers the power to the driving wheel and other components through the output shaft to make the vehicle or equipment move.

Variable speed principle: Change the transmission ratio by meshing gears with different numbers of teeth. For example, when the big gear drives the small gear, the speed of the small gear will be faster than the big gear, but the output torque will be smaller, to achieve growth and torque reduction; On the contrary, when the pinion drives the big gear, the speed of the big gear slows down, the torque increases, and the torque increases. In this way, transmission gears enable the vehicle or equipment to obtain the right speed and torque under different working conditions -

Transmission Gear

Transmission GearTransmission Gear are vital components in machinery, particularly in heavy-duty equipment such as tractors, harvesters, and construction machinery. These gears play a crucial role in transmitting power from the engine to the wheels, ensuring smooth and efficient operation. Designed for durability, Transmission Gear are made from high-quality materials like steel and alloy to withstand the immense stresses and high temperatures encountered during operation.

-

Tractor Active Gear Shaft

Tractor Active Gear ShaftThe tractor active gear shaft is a critical component in the power transmission system of a tractor, responsible for transferring rotational power from the engine or transmission to other parts of the tractor. By efficiently distributing torque and enabling smooth gear shifts, the active gear shaft plays a vital role in enhancing the performance and versatility of the tractor, making it essential for a wide range of agricultural tasks. In this article, we’ll explore the function, benefits, and maintenance of the tractor active gear shaft.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

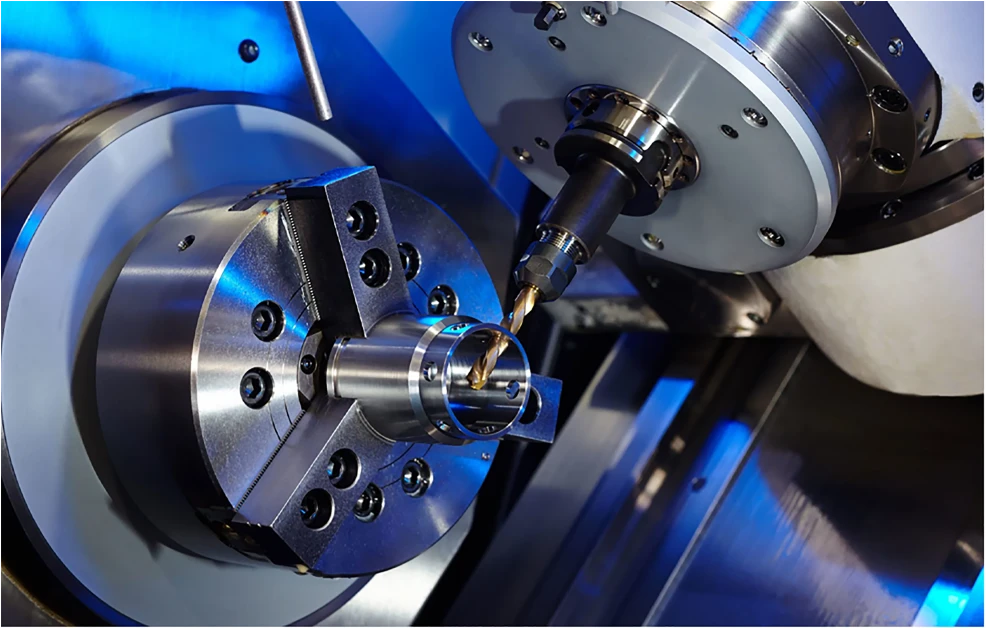

Precision Gear Quality Inspection – Ensuring Optimal Performance

Our advanced gear quality inspection guarantees precise measurements, durability assessment, and defect detection, ensuring every gear meets the highest industry standards for performance and reliability.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates