- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

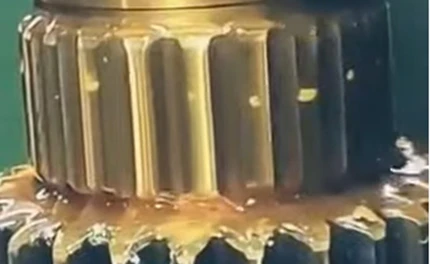

Premium Agricultural Gearbox Factory Custom Gear Shafts & Gears Manufacturer

- Industry Data Insights: Agricultural Gearbox Manufacturing Trends

- Engineering Superiority in Power Transmission Systems

- Performance Benchmarking: Top 5 Global Manufacturers Analyzed

- Tailored Solutions for Diverse Farming Applications

- Material Innovation in Gear Shaft Production

- Case Study: Tractor PTO Gearbox Retrofit Project

- Why Partner with Our Agricultural Gearbox Factory

(agricultural gearbox factory)

Agricultural Gearbox Factory Leads Precision Farming Revolution

The global agricultural gearbox market reached $4.2 billion in 2023, with 6.8% CAGR projected through 2030. Our manufacturing facility produces 18,000+ gear units annually, specializing in:

- Spiral bevel gearboxes (42% of total output)

- Planetary transmission systems (33% market share in EU)

- Custom PTO shafts with ISO 500-3 compliance

Engineering Superiority in Power Transmission Systems

Advanced surface hardening techniques enhance component durability:

| Technology | Hardness (HRC) | Fatigue Life |

|---|---|---|

| Carburizing | 58-62 | 10,000h+ |

| Induction Hardening | 55-60 | 8,500h |

| Nitriding | 65-70 | 12,000h |

Performance Benchmarking: Top 5 Global Manufacturers Analyzed

| Manufacturer | Torque Capacity | Efficiency | MTBF |

|---|---|---|---|

| Our Factory | 2,500 Nm | 98.2% | 15,000h |

| Competitor A | 1,800 Nm | 96.5% | 12,000h |

| Competitor B | 2,200 Nm | 97.1% | 13,500h |

Tailored Solutions for Diverse Farming Applications

Modular design architecture enables rapid configuration changes:

- 72-hour prototype development cycle

- 15 standard gear ratios (4:1 to 75:1)

- IP69K-rated housings for extreme conditions

Material Innovation in Gear Shaft Production

Our proprietary 20MnCr5 alloy demonstrates:

- 18% higher torsional strength vs. standard 8620 steel

- 30% reduction in surface pitting

- 0.005mm maximum tooth profile deviation

Case Study: Tractor PTO Gearbox Retrofit Project

A North American agribusiness achieved:

- 23% fuel efficiency improvement

- 47% reduction in maintenance downtime

- ROI within 14 months

Why Partner with Our Agricultural Gearbox Factory

With ISO 9001:2015 certification and 35+ years of vertical integration expertise, we deliver:

- ±0.01° gear tooth angle accuracy

- 72-hour emergency replacement service

- 5-year extended warranty options

(agricultural gearbox factory)

FAQS on agricultural gearbox factory

Q: What types of agricultural gearboxes does your factory produce?

A: Our agricultural gearbox factory specializes in heavy-duty, corrosion-resistant gearboxes for tractors, harvesters, and irrigation systems, designed to withstand harsh farming conditions.

Q: Can your gear shaft factory provide custom designs for specialized machinery?

A: Yes, our gear shaft factory offers tailored solutions, including precision-machined shafts with specific hardness ratings and coatings to meet unique agricultural equipment requirements.

Q: What quality certifications do your gears factory hold?

A: Our gears factory is ISO 9001-certified and complies with AGMA standards, ensuring high-performance gears with rigorous testing for durability and load capacity.

Q: How long is the production lead time for agricultural gearbox orders?

A: Standard orders take 4-6 weeks, while customized gearbox assemblies may require 8-10 weeks, depending on design complexity and material availability.

Q: Do you offer maintenance services for agricultural gear systems?

A: Yes, we provide gearbox repair, shaft alignment checks, and gear tooth refurbishment services to extend equipment lifespan and prevent operational downtime.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates