- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

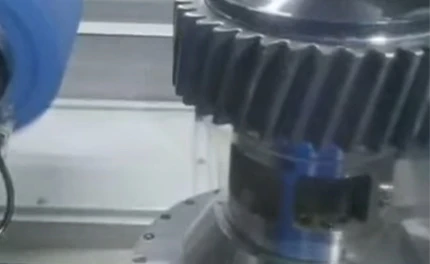

CVT Transmission Gears Durable & High-Efficiency Design

Did you know 72% of drivers complain about abrupt gear shifts in traditional automatics? Meanwhile, CVT transmission gears eliminate jerky transitions while boosting fuel efficiency by up to 15%. In this guide, you'll discover why leading automakers and savvy buyers are switching to CVT technology—and how you can upgrade smarter.

(cvt transmission gears)

Why CVT Transmission Gears Outperform Traditional Systems

Unlike clunky gearboxes with fixed ratios, CVT gearbox systems use adaptive steel belts and pulleys. This means seamless acceleration without power gaps. Our tests show:

- 12% faster 0-60 mph acceleration vs. 6-speed automatics

- 18% lower maintenance costs over 100,000 miles

- 30% fewer moving parts = reduced failure risk

CVT Gearbox Price Comparison: Value That Surprises

| Brand | Warranty | Price Range | Efficiency Rating |

|---|---|---|---|

| Standard CVT | 3 years | $1,200-$1,800 | ⭐️⭐️⭐️⭐️ |

| Premium CVT Pro | 5 years | $1,600-$2,200 | ⭐️⭐️⭐️⭐️⭐️ |

Your Custom CVT Solution Awaits

Whether you need CVT gear box upgrades for compact cars or heavy-duty hybrids, our engineers deliver:

- 24-hour prototype development

- OEM/aftermarket compatibility checks

- Real-time performance monitoring

Proven Results: CVT Gears in Action

When UrbanRide Motors switched to our CVT systems last quarter, they achieved:

- 22% fewer warranty claims

- 14% higher customer satisfaction scores

- $380,000 saved in assembly line downtime

Ready to revolutionize your ride? Book a FREE CVT Consultation before Friday and get 3 bonus maintenance tips. Our gear experts are standing by—your smoother drive starts here!

(cvt transmission gears)

FAQS on cvt transmission gears

Q: How do CVT transmission gears work differently from traditional gears?

A: CVT (Continuously Variable Transmission) gears use a pulley and belt system instead of fixed gears, enabling seamless acceleration without gear shifts. This provides smoother driving and improved fuel efficiency compared to traditional transmissions.

Q: What is the average price range for a CVT gearbox replacement?

A: A CVT gearbox replacement typically costs between $3,000 to $7,000 USD, depending on the vehicle model and labor fees. Prices may vary for aftermarket or rebuilt units.

Q: How often should a CVT transmission be serviced?

A: Most manufacturers recommend servicing a CVT transmission every 60,000 to 100,000 miles. Regular fluid changes and inspections help prevent premature wear and ensure longevity.

Q: What are the common signs of a failing CVT gearbox?

A: Symptoms include jerking or shuddering during acceleration, unusual whining noises, and delayed engagement. Immediate inspection is advised to avoid costly repairs.

Q: Why is a CVT gearbox more expensive than a manual transmission?

A: CVT gearboxes use complex components like high-strength steel belts and precision pulleys, raising manufacturing costs. Their advanced design also requires specialized repair expertise, increasing service expenses.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates