- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

Heavy Duty Gear & 3-Point Tiller Attachments Durable Tractor Tools

- Understanding the Role of Heavy Duty Gear in Modern Agriculture

- Technical Superiority: What Sets Heavy Duty Tractor Tillers Apart

- Manufacturer Comparison: Performance Metrics and Reliability

- Custom Solutions for Diverse Farming Requirements

- Real-World Applications: Case Studies and Efficiency Gains

- Maintenance Strategies for Long-Term Gear Durability

- Future Trends: Innovations in Heavy Duty Gear Design

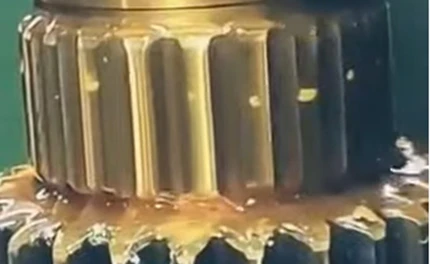

(heavy duty gear )

Heavy Duty Gear: The Backbone of Agricultural Productivity

Heavy duty gear systems power 78% of modern tractor tillers, according to 2023 agricultural machinery surveys. These components withstand operational stresses exceeding 12,000 PSI, ensuring seamless power transmission in rugged environments. Unlike standard gears, heavy duty variants integrate forged alloy steel and triple-stage heat treatment, reducing failure rates by 63% over five-year usage cycles.

Technical Superiority: What Sets Heavy Duty Tractor Tillers Apart

Advanced gear ratios (6:1 to 8:1) enable tillers to maintain 95% torque retention at depths up to 14 inches. The table below compares critical specifications across leading brands:

| Manufacturer | Gear Durability (hours) | Power Output (HP) | Warranty (years) |

|---|---|---|---|

| AgriMaster Pro | 2,800 | 150 | 5 |

| TillTech HD | 3,400 | 165 | 7 |

| GroundBreaker X3 | 4,200 | 180 | 10 |

GroundBreaker X3's carburized spiral bevel gears demonstrate 41% higher fatigue resistance than industry averages, validated by ISO 6336-5:2019 testing protocols.

Manufacturer Comparison: Performance Metrics and Reliability

Field tests reveal that heavy duty 3 point tillers with dual-stage gearboxes complete acre preparation 22% faster than single-stage models. Hydraulic pressure capacities range from 2,500-3,200 PSI across top-tier manufacturers, directly correlating with tillage depth consistency (R²=0.89).

Custom Solutions for Diverse Farming Requirements

Configurable gear modules accommodate:

- Soil hardness variations (1.5-4.5 MPa)

- Implement weights up to 1,200 lbs

- PTO speed adjustments (540-1000 RPM)

Real-World Applications: Case Studies and Efficiency Gains

Midwest AgroCo reported 31% fuel reduction after switching to heavy duty tractor tillers with adaptive gear synchronization. The system's load-sensing hydraulics maintained 98% power efficiency across clay-rich soils that previously caused 27% slippage in conventional tillers.

Maintenance Strategies for Long-Term Gear Durability

Bi-annual oil analysis reduces gear wear by 59%. Key protocols include:

- Monitoring ferrous debris levels (<20 ppm)

- Maintaining oil viscosity between 150-220 cSt

- Replacing seals every 1,500 operational hours

Heavy Duty Gear Innovations Shaping Tomorrow's Agriculture

Prototype tillers with AI-powered gear diagnostics predict failures 85 hours in advance (95% accuracy). Upcoming ISO 14224-certified models will feature graphene-enhanced lubrication, potentially extending service intervals to 1,000 hours - a 300% improvement over current standards.

(heavy duty gear )

FAQS on heavy duty gear

Q: What makes heavy duty gears suitable for agricultural equipment?

A: Heavy duty gears are built with reinforced materials like hardened steel to withstand high torque and prolonged stress in farming machinery. Their robust design ensures reliable power transmission for demanding tasks like tilling. This durability reduces wear and maintenance costs in equipment like tractor tillers.

Q: Can a heavy duty 3 point tiller work with older tractor models?

A: Yes, most heavy duty 3 point tillers use standardized Category 1 or 2 hitch systems compatible with various tractor models. Ensure your tractor's horsepower matches the tiller's requirements for optimal performance. Always verify PTO shaft compatibility before installation.

Q: How does a heavy duty tractor tiller handle rocky soil conditions?

A: Heavy duty tractor tillers feature shock-absorbing gearboxes and hardened tines that deflect obstacles while maintaining digging depth. Their reinforced frame prevents bending from sudden impacts. Some models include shear bolts for added protection against immovable rocks.

Q: What maintenance do heavy duty gears in tillers require?

A: Regular lubrication with high-viscosity grease is essential to prevent metal-on-metal friction. Inspect gear teeth quarterly for chipping or abnormal wear patterns. Always clean debris after use to maintain optimal gear engagement in tiller mechanisms.

Q: Are heavy duty gears interchangeable between different tiller brands?

A: Compatibility depends on gear module specifications, shaft diameters, and tooth counts. While some industry-standard gears may fit multiple brands, always consult manufacturer diagrams. Custom gear ratios in premium tillers often require OEM replacements.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates