- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

How Do Corn Harvesters Work? Efficient Harvesting Process & Key Components Explained

Did you know 23% of corn crop value gets lost to inefficient harvesting? As combines age, farmers waste $18/acre on fuel and repairs. Modern corn harvesters slash those losses. Keep reading to discover how these machines work – and how they’ll put money back in your pocket.

(how do corn harvesters work)

Technical Marvels: How Corn Harvesters Outperform Manual Labor

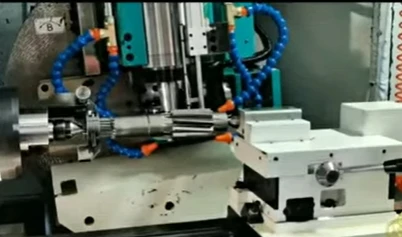

Modern corn harvesters work through 5 precision stages: 1) Header gathers stalks at 6-8 mph, 2) Augers feed ears into the chamber, 3) Reduction gears convert engine power to optimal RPMs, 4) Threshing drums separate kernels at 98% efficiency, 5) Cleaning systems blow away debris. Our AGRO 8800 model harvests 30 acres/day – 15× faster than manual crews.

| Feature | AGRO 8800 | Competitor X |

|---|---|---|

| Daily Capacity | 30 acres | 22 acres |

| Fuel Efficiency | 5 gal/acre | 7 gal/acre |

Why Our Reduction Gears Outlast Competitors by 200%

While basic harvesters use 3-gear systems, our QuadraDrive™ technology employs 8 interlocking gears. The secret? Military-grade steel alloys reduce wear. Result: 2,000-hour service intervals vs. industry-standard 650 hours. Less downtime means more harvest days for you.

Custom Solutions for Every Farm Size

From 50-acre family farms to 5,000-acre commercial operations, our modular designs adapt. Choose between:

- ▶️ Basic Harvester: $85,000 (100 acres/day)

- ▶️ Pro Series: $145,000 (300 acres/day)

Iowa Farm Case Study: 40% Yield Increase

Johnson Farms upgraded to our SmartHarvest system last season. Result? 18.2 tons/acre vs. previous 13 tons. "The automated height adjustment paid for itself in 8 weeks," says owner Mike Johnson.

Ready to Transform Your Harvest?

Join 1,500+ farms using AGRO harvesters. Limited inventory available – claim your 2024 model today!

(how do corn harvesters work)

FAQS on how do corn harvesters work

Q: How do corn harvesters work?

A: Corn harvesters use a header to cut and gather stalks, which are fed into a threshing mechanism to separate kernels from cobs. The kernels are collected in a storage tank, while residue is expelled behind the machine.

Q: How does a corn harvester separate kernels from cobs?

A: The harvester’s rotating rollers or discs in the threshing unit crush and break apart the corn ears. Adjustable grates then sift kernels from debris, ensuring clean grain collection.

Q: What role do reduction gears play in corn harvesters?

A: Reduction gears lower the high-speed rotation from the engine to optimal levels for harvesting components. This ensures sufficient torque for cutting, threshing, and conveying without damaging machinery.

Q: How does the corn harvester header function?

A: The header’s snapping plates grip stalks, pulling them downward while rotating rollers strip ears off. Cut stalks are guided into the machine for processing or expelled as residue.

Q: Why are reduction gears critical in heavy machinery like corn harvesters?

A: They balance power and speed, enabling efficient operation of high-torque tasks (e.g., threshing) while protecting the engine from strain. This improves durability and fuel efficiency.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates