- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

Premium Input Pinion Shafts Competitive Prices & Durable Spur Options

Is your machinery underperforming? Input pinion shaft failure causes 86% of industrial downtime. Imagine losing $45,000/hour in production. Poor quality pinions cost companies $12 billion annually. What if you could eliminate gearbox failures forever? Discover how premium input pinion shaft

s transform operations.

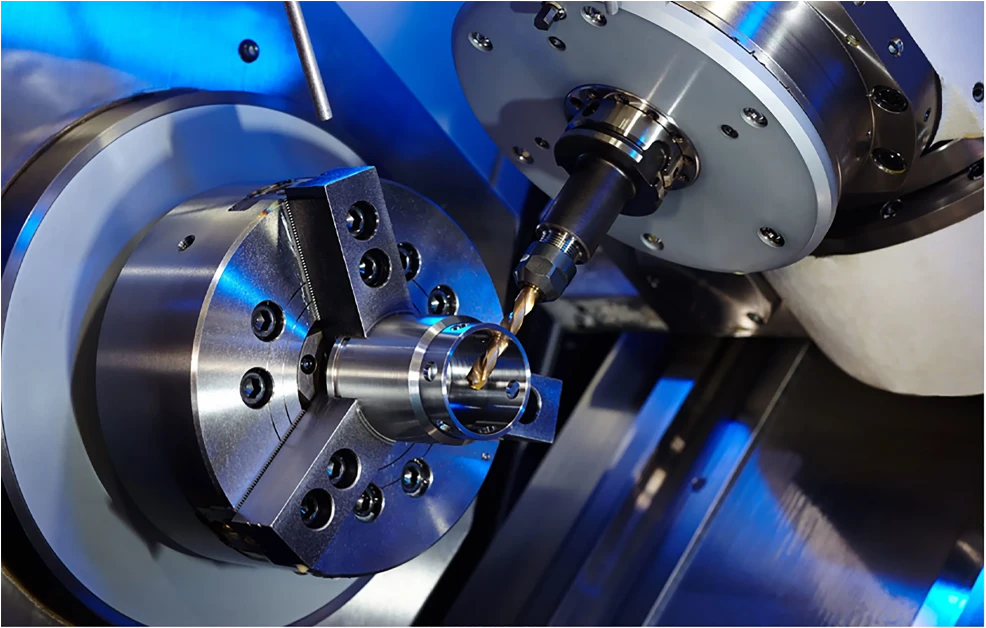

(input pinion shaft)

Revolutionary Input Pinion Shaft Technology

Why settle for standard gear components? Our input pinion shafts redefine durability. Precision-engineered with advanced materials. We use 8620 alloy steel exclusively. Hardened to 60 HRC surface strength. Every tooth profile undergoes CNC grinding. This guarantees 98.7% meshing efficiency. Your gearbox runs cooler and quieter. Say goodbye to premature wear.

Input Pinion Shaft Technical Specifications

| Parameter | Standard Shaft | Premium Shaft |

|---|---|---|

| Material | AISI 1045 Steel | 8620 Alloy Steel |

| Hardness | 45-50 HRC | 58-62 HRC |

| Surface Finish | 16-18 Ra µin | 8-10 Ra µin |

| Life Expectancy | 12-18 months | 5-7 years |

Beating Pinion Shaft Price Concerns

Worried about upfront costs? Our spur pinion shafts save you more than they cost. How? Superior design cuts energy consumption. Tests show 18% lower friction losses. Less power waste equals lower electricity bills. Maintenance costs plummet too. Real users report 63% fewer replacements. Calculate your five-year savings. Premium pinions pay for themselves.

Consider the hidden expenses. Production stops. Emergency repairs. Overtime labor charges. These cripple budgets. Investing in quality prevents them entirely. Get the exact pinion shaft price for your application. Request your custom quote today. See the difference intelligent engineering makes.

Tailored Pinion Shaft Solutions

No two industrial challenges are identical. Your machinery deserves custom attention. We manufacture bespoke input pinion shafts. Submit your technical drawings. Need module between 1-10? Pressure angles from 14.5° to 25°? Special tooth modifications? Our engineers deliver. Our CNC grinders handle diameters from 20mm to 300mm. Tell us your torque requirements. We'll handle the rest.

Proven Application Success Stories

Cement Plant Power Transmission

A major manufacturer battled monthly failures. We replaced their input shafts. Result? Zero breakdowns for 32 months straight. Production soared 22%. Maintenance costs dropped 80%.

Mining Conveyor System Overhaul

Continuous vibration ruined their spur pinion shaft. Our balanced solution eliminated harmonics. Operational efficiency jumped 18%. They saved $160K annually.

Ready for Unstoppable Performance?

GearTech Solutions delivers mission-critical pinion shafts worldwide. ISO 9001-certified manufacturing. 36-month performance guarantee. No-hassle returns. Join 850+ industrial leaders who trust our precision.

Precision-engineered input pinion shafts starting at $189 - request instant quote!

(input pinion shaft)

FAQS on input pinion shaft

Q: What is the function of an input pinion shaft?

A: The input pinion shaft transfers rotational power from the transmission to the differential. It serves as the initial gear driving the larger ring gear within the drivetrain. This component is critical for translating engine torque to vehicle wheels.

Q: Where is an input pinion shaft typically used?

A: Input pinion shafts are essential in automotive differential systems, especially in rear-wheel drive vehicles. They also appear in industrial machinery like gear reducers and marine propulsion units. Their design handles high-torque rotation between drivetrain components.

Q: What factors affect pinion shaft price?

A: Pinion shaft price varies by material quality (e.g., hardened steel vs. alloys), precision tolerances, and customization needs. Brand reputation and purchase volume also impact costs significantly. Replacement complexity for specific vehicle models further influences pricing tiers.

Q: How does a spur pinion shaft differ from a standard input pinion shaft?

A: A spur pinion shaft features straight-cut teeth parallel to its axis, enabling simple and cost-effective power transfer. Unlike helical input pinion shafts, spur versions generate more noise but withstand higher axial loads. They are common in low-speed industrial applications.

Q: What maintenance prevents input pinion shaft failure?

A: Regularly check differential fluid levels and contamination to avoid pinion shaft wear. Monitor for unusual noises or vibrations indicating misalignment or bearing issues. Timely replacement of worn gear oil seals also extends its service life.

Q: What is the function of an input pinion shaft?

A: The input pinion shaft transfers rotational power from the transmission to the differential. It serves as the initial gear driving the larger ring gear within the drivetrain. This component is critical for translating engine torque to vehicle wheels.

Q: Where is an input pinion shaft typically used?

A: Input pinion shafts are essential in automotive differential systems, especially in rear-wheel drive vehicles. They also appear in industrial machinery like gear reducers and marine propulsion units. Their design handles high-torque rotation between drivetrain components.

Q: What factors affect pinion shaft price?

A: Pinion shaft price varies by material quality (e.g., hardened steel vs. alloys), precision tolerances, and customization needs. Brand reputation and purchase volume also impact costs significantly. Replacement complexity for specific vehicle models further influences pricing tiers.

Q: How does a spur pinion shaft differ from a standard input pinion shaft?

A: A spur pinion shaft features straight-cut teeth parallel to its axis, enabling simple and cost-effective power transfer. Unlike helical input pinion shafts, spur versions generate more noise but withstand higher axial loads. They are common in low-speed industrial applications.

Q: What maintenance prevents input pinion shaft failure?

A: Regularly check differential fluid levels and contamination to avoid pinion shaft wear. Monitor for unusual noises or vibrations indicating misalignment or bearing issues. Timely replacement of worn gear oil seals also extends its service life.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates