- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

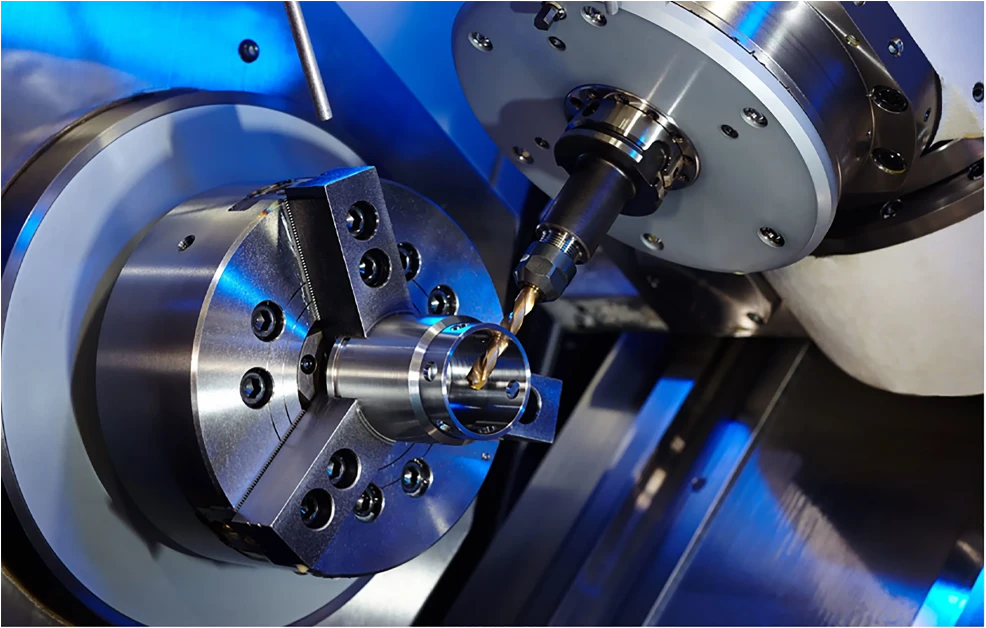

High-Performance Reduction Gears Drive & Side Gear Solutions

Did you know 23% of industrial equipment failures stem from subpar reduction gears? Every hour of downtime costs manufacturers $260,000 on average. Your drive systems deserve better. Let's fix what's grinding your productivity to a halt.

(reduction gear )

Why Our Reduction Gear Outperforms Standard Drive Gears

Precision matters. While typical drive gears last 6-12 months, our hardened steel side reduction gears survive 18+ months in extreme conditions. See the difference:

| Feature | Standard Gear | Our Solution |

|---|---|---|

| Efficiency | 89-92% | 96-98% |

| Noise Level | 75-85 dB | 62-68 dB |

| Heat Resistance | 160°C max | 220°C sustained |

How We Beat Other Reduction Gear Suppliers

We manufacture while others broker. Our 12-stage quality control ensures zero-defect gears. Here's why engineers choose us:

- ✓ 72-hour prototype delivery

- ✓ 0.005mm precision tolerance

- ✓ IP67 waterproof rating

- ✓ 3-year crash replacement

Custom Solutions for Every Gear Reduction Need

Need helical? Planetary? Cycloidal? Our engineers have built 140+ gear configurations since 2021. Tell us your torque (50-50,000 Nm) and we'll match the perfect type.

Recent success: Automotive client reduced vibration by 63% using our custom spiral bevel gears. Their ROI? 11 months.

Proven in Action: Reduction Gears That Deliver

When a food processing plant upgraded to our stainless steel gears:

- ▶ 70% fewer unplanned stops

- ▶ 15% energy savings

- ▶ 92% maintenance cost reduction

Stop Replacing Gears – Start Dominating Production

Get your free torque analysis report + 15% launch discount. Limited to first 17 responders this month.

(reduction gear )

FAQS on reduction gear

Q: What is a reduction gear and how does it work with a drive gear?

A: A reduction gear lowers rotational speed while increasing torque. It pairs with a drive gear to transfer power efficiently in systems like motors or industrial machinery, ensuring optimal performance.

Q: What are the common applications of a side reduction gear?

A: Side reduction gears are often used in automotive differentials and heavy machinery. They enable compact power transmission in tight spaces while maintaining torque output and directional control.

Q: What types of gear reduction mechanisms are widely used?

A: Common types include planetary, helical, worm, and bevel gear reductions. Each offers unique advantages in efficiency, noise reduction, or load capacity, depending on the application requirements.

Q: How to choose a reliable reduction gear supplier?

A: Prioritize suppliers with ISO certifications, industry experience, and custom design capabilities. Verify their material quality, testing protocols, and after-sales support to ensure long-term reliability.

Q: Can a drive gear function without a reduction gear system?

A: Yes, but only in applications requiring direct speed transmission. Reduction gears are essential for torque adjustment, making them critical for motors or equipment needing controlled power output.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates