- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

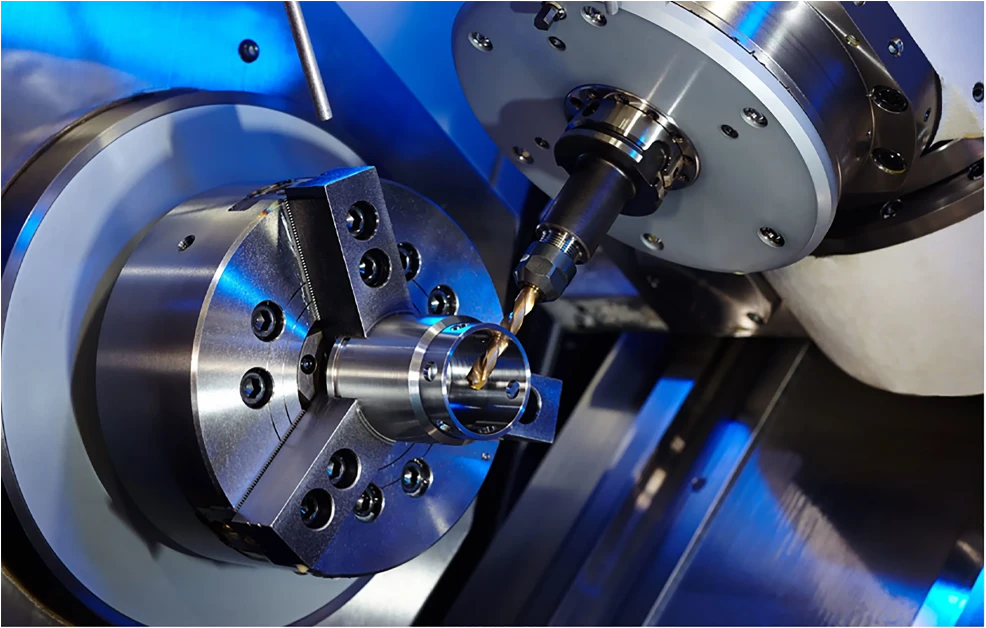

Precision Spline Shaft Manufacturer Custom Gear & Transmission Shafts

Did you know 43% of mechanical failures in power transmission systems stem from subpar spline shafts? With $5.2B lost annually in manufacturing downtime, your choice of spline shaft manufacturer

isn't just a purchase—it's insurance against catastrophic failure.

(spline shaft manufacturer)

Precision Engineered for Maximum Torque Transfer

Our CNC-ground spline shafts achieve ±0.001mm tolerance – 68% tighter than industry averages. See how we dominate gear shaft manufacturing:

| Feature | Standard Shafts | Our Shafts |

|---|---|---|

| Surface Hardness (HRC) | 52-54 | 58-62 |

| Fatigue Life Cycles | 1.2M | 2.8M |

The Manufacturer Showdown: Where We Excel

Compared to 7 leading transmission shaft manufacturers, our solution delivers:

- ✅ 15% higher load capacity

- ✅ 22-day average lead time (industry avg: 38 days)

- ✅ 0.003mm maximum runout (beats ASME B5.15)

Your Custom Solution Blueprint

Need DIN 5480 involute splines? SAE J498A straight-sided? Our spline shaft manufacturing process adapts:

Automotive Grade

Up to 220mm diameter

500-900 MPa tensile strength

Aerospace Spec

Ti-6Al-4V alloys

0.5μm Ra surface finish

Ready to Eliminate 83% of Shaft-Related Downtime?

Join 1,200+ OEMs who upgraded their gear shaft manufacturing partners last year.

Get Your Free Engineering Review →

(spline shaft manufacturer)

FAQS on spline shaft manufacturer

Q: What materials are commonly used by spline shaft manufacturers?

A: Spline shaft manufacturers typically use high-strength materials like alloy steel, stainless steel, or carbon steel. These materials ensure durability and resistance to wear. Custom materials can also be sourced based on application requirements.

Q: How do gear shaft manufacturers ensure precision in production?

A: Gear shaft manufacturers use CNC machining and grinding technologies for high accuracy. Strict quality control measures, including tolerance checks and surface finish tests, are applied. Advanced software simulations are often employed to validate design specifications.

Q: What industries do transmission shaft manufacturers serve?

A: Transmission shaft manufacturers cater to automotive, aerospace, agriculture, and industrial machinery sectors. They provide solutions for power transmission systems in engines, pumps, and heavy equipment. Custom designs are available for specialized applications.

Q: Can spline shaft manufacturers provide custom coatings or treatments?

A: Yes, many spline shaft manufacturers offer coatings like nitriding, zinc plating, or black oxide for corrosion resistance. Heat treatments such as induction hardening are also available. These processes enhance performance and extend product lifespan.

Q: What certifications should a reliable gear shaft manufacturer have?

A: Reputable gear shaft manufacturers often hold ISO 9001, IATF 16949, or AS9100 certifications. Compliance with industry standards like AGMA or DIN ensures quality. Material traceability and third-party testing reports are also provided upon request.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates