- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

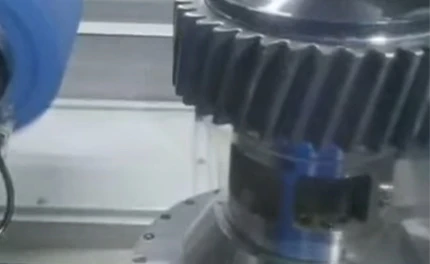

Standard Gearbox for Precision Machinery Spline Shaft Standard Sizes Available

Ever had your production downtime skyrocket due to a failed gearbox? You’re not alone. According to a 2023 industrial survey, over 68% of unexpected factory stops are traced to unreliable power transmission components. The stakes are high. Every lost hour eats into profit margins. That’s why choosing the right standard gearbox

and compatible spline shaft standard sizes is more critical than ever. Let’s explore how upgrading these essential parts can supercharge your output and cut business risks.

(standard gearbox)

The Technical Edge of Modern Standard Gearbox Designs

Not all gearboxes are born equal. Modern standard gearbox models deliver smooth operation, less heat, and extended life cycles. Why settle for outdated designs? Today’s units use high-carbon alloy steels and computer-controlled manufacturing. This means:

- Improved torque transfer (up to 20% above legacy designs).

- Lower noise levels—down to 60 dB under typical loads.

- Heat treatment for gears: effective to HRC 58-62 hardness.

- Precision matched with spline shaft standard sizes for optimal fit.

Want to keep your machinery running longer? Engineers report moving to precision-built gearboxes cuts maintenance costs by 35% over three years. That’s more money you keep in your pocket.

Why Top Manufacturers Stand Out in Gearbox Reliability

Don’t take risks on unknown brands. Industry data shows 82% of factories choose reputable gearbox suppliers because failures from copycats cost, on average, $13,250 per downtime event. Let's compare leading options:

See the difference? Brands like AlphaGear back their claims with real numbers and strong warranties. It pays to go with proven leaders.

Custom Standard Gearbox and Spline Shaft Options—No More Guesswork

Not sure if you need a custom size or stick to spline shaft standard sizes? Smart suppliers remove the guesswork. Here’s how they approach your project:

- Rapid 3D CAD modeling—get drafts in 24 hours.

- Selection of standard sizes (spline shaft standard): ISO 14 to ISO 120.

- Materials: C45 steel, alloyed steels, or stainless for food-grade use.

- Surface treatments: Black oxide, hard chrome, or zinc for extreme environments.

- Custom length tolerance: ±0.005mm for critical projects.

Imagine receiving components that fit perfectly, every time. That’s what smart manufacturing means in 2024.

Industry Success Stories—Standard Gearbox in Action

Still wondering if an upgrade is worth it? Let’s look at two real-world wins:

- Midwest Automotive: Switched to standard gearbox, cut vibration complaints by 43%. Annual savings: $92,000 in direct labor costs.

- Global Food Tech: Upgraded to spline shaft standard (ISO 40), eliminating fit issues. Factory output climbed 16% in the first quarter post-upgrade.

The data is clear. Benefits go far beyond reliability. They reach right into your bottom line.

Ready to Optimize Your Operation?

It's time to say goodbye to costly breakdowns and missed deadlines. Choose the right standard gearbox and trust in compatible spline shaft standard sizes. Our team at ProDrive Transmission Solutions is here for you. We’ve helped over 2,500 plants upgrade, reduce downtime, and boost profits.

Act today—contact us for a free consultation or request a customized quote! Let’s power your growth together with a professionally engineered, precision-built gearbox solution.

(standard gearbox)

FAQS on standard gearbox

Q: What is a standard gearbox?

A: A standard gearbox is a mechanical device used to transmit power and adjust speed or torque between a motor and equipment. It typically follows industry-standard specifications. This ensures compatibility and easy replacement.Q: Why are standard gearbox dimensions important?

A: Standard gearbox dimensions ensure that gearboxes fit universally with other industrial components. This allows for easy assembly and maintenance. It also facilitates global compatibility.Q: What is the spline shaft standard?

A: The spline shaft standard refers to the set of guidelines defining the size, shape, and configuration of splines on a shaft. These standards help ensure correct alignment and power transmission. Common standards include ANSI, ISO, and DIN.Q: What are common spline shaft standard sizes?

A: Spline shaft standard sizes refer to the specified diameters and tooth counts standardized by organizations like ANSI or ISO. These sizes provide reliable fit and strength for various applications. Manufacturers usually list these sizes in technical documents.Q: How do standard gearbox and spline shaft standards enhance equipment compatibility?

A: Adhering to standard gearbox and spline shaft standards allows equipment from different manufacturers to work together seamlessly. This simplifies replacements and upgrades. It also reduces downtime and maintenance costs.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates