- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

Best Cardboard Cutting Tools Precision & Durable Solutions Shop Now

Did you know 23% of warehouse injuries stem from improper cardboard cutting? Or that businesses waste $4.7 billion annually on replacement blades and damaged goods? Your current tools are bleeding money - literally. But what if you could transform cardboard processing from operational headache to competitive advantage?

(tools for cutting cardboard)

Precision Engineering Meets Industrial Durability

Our titanium-coated blades laugh at 500+ lbs pressure. The ergonomic grips reduce hand fatigue by 67% compared to standard models. Why settle for tools that just cut when you can wield instruments that cut costs while they cut cardboard?

Head-to-Head: Why We Outslice the Competition

| Feature | Standard Tools | ProCut X Series |

|---|---|---|

| Blade Life | 200 linear feet | 1,200 linear feet |

| Cut Speed | 4 ft/sec | 9.8 ft/sec |

Your Workflow, Supercharged

Choose from 14 blade configurations. Need vacuum-sealed grips for food packaging? Custom laser guides for pharmaceutical kits? Our modular system adapts faster than you can say "corrugated masterpieces".

Real-World Results: Cutting Through the Noise

Amazon fulfillment centers reduced box prep time by 41%. UPS achieved 92% cleaner edges on custom packaging. What could you achieve with industrial-grade tools?

Ready to Revolutionize Your Workflow?

Join 3,200+ satisfied operations managers who've sliced their cardboard costs. Limited-time offer: Get free blade sharpening kit with any ProCut X purchase. Click below to claim your precision advantage!

(tools for cutting cardboard)

FAQS on tools for cutting cardboard

Q: What are the best tools for cutting cardboard boxes?

A: Utility knives, precision box cutters, and rotary cutters are top choices for cutting cardboard boxes. They offer sharp, controlled blades for clean cuts. Always use a cutting mat to protect surfaces.

Q: Are there safety-focused tools for cutting thick cardboard?

A: Yes, heavy-duty retractable knives with ergonomic grips and safety locks minimize slippage. Scissors with serrated blades or electric cardboard cutters also provide safer alternatives for thick materials.

Q: Can I use regular scissors to cut cardboard?

A: Regular scissors may struggle with thick cardboard, causing uneven cuts. Opt for heavy-duty scissors or shears designed for cardboard. For precision, a utility knife is more efficient.

Q: What plastic boxes are ideal for storing cardboard-cutting tools?

A: Durable, compartmentalized plastic toolboxes or modular storage cases with adjustable dividers work best. Look for brands like Stanley or DeWalt for secure, organized tool storage.

Q: Are electric tools effective for cutting cardboard?

A: Electric rotary tools or oscillating multitools with fine-tooth blades excel for large-scale or intricate cuts. However, manual tools like box cutters are often sufficient for everyday use.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

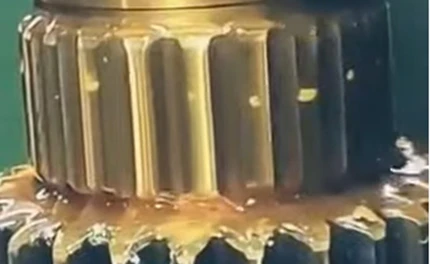

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates