- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

Best Tractor Selection & 48/4 Tiller Attachments Expert Picks

(tractor selection)

The $6.7 Billion Question: Are You Choosing the Right Tractor? (Most Farmers Don't)

Did you know 68% of farm operators report efficiency losses from mismatched equipment? With global tractor sales hitting $6.7B in 2023, why do 3 in 5 buyers still settle for underperforming machines? Your tractor selection

directly impacts 42% of field productivity. Let's fix that.

Engineering Excellence: Where 48" Tiller Meets Smart Power

Our 4 tractor tiller systems outperform competitors where it counts:

→ 15% deeper soil penetration

→ 22% less fuel consumption

→ 40 hardened steel blades

→ 5-year drivetrain warranty

| Feature | Our 48" Tiller | Brand X | Brand Y |

|---|---|---|---|

| HP Compatibility | 35-70HP | 45-65HP | 40-60HP |

| Warranty | 5 years | 3 years | 2 years |

Your Land, Your Rules: Precision Matching System

Our SmartMatch algorithm analyzes:

→ Soil type (clay/sand/loam density)

→ Plot size (1-500+ acres)

→ Crop rotation patterns

→ Local climate factors

Real Results: Iowa Farm Case Study

"After matching our 48 tiller for tractor with the RX-450 model, we achieved:

▲ 31% faster field prep

▼ 19% lower diesel costs

0 unplanned maintenance in 18 months"

- J. Anderson, 240-acre corn/soy operation

Ready to join 12,000+ satisfied farms?

Claim your FREE Tractor Selection Guide + $500 seasonal discount!

(tractor selection)

FAQS on tractor selection

Q: What factors should I consider when selecting a tractor for a 48 tiller?

A: Prioritize tractor horsepower (35-50 HP recommended), PTO compatibility, and hydraulic capacity to efficiently power a 48" tiller. Ensure weight distribution matches soil conditions for optimal tillage depth and stability.

Q: Can a 4-wheel drive tractor improve performance with heavy-duty tillers?

A: Yes, 4WD tractors provide better traction for 4-tractor tillers in wet or uneven terrain. Enhanced torque distribution reduces slippage and ensures consistent tilling depth across challenging fields.

Q: How do I match a tractor's PTO speed to a 48" tiller's requirements?

A: Verify the tiller's required RPM (usually 540 RPM standard) aligns with your tractor's PTO settings. Modern tractors often feature dual-speed PTOs to accommodate implements like 48 tillers for versatile farming operations.

Q: Are compact tractors suitable for operating 4-tractor tillers?

A: Compact 25-35 HP tractors can handle smaller 4-tractor tillers in light soils, but mid-range 40+ HP models are better for clay or rocky soils. Always check the tiller manufacturer's horsepower recommendations.

Q: What maintenance checks are vital when pairing a tractor with a 48 tiller?

A: Inspect PTO shaft lubrication, tiller blade sharpness, and tractor hydraulic fluid levels before use. Regularly monitor tire pressure and 3-point hitch alignment to prevent uneven tilling and equipment strain.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

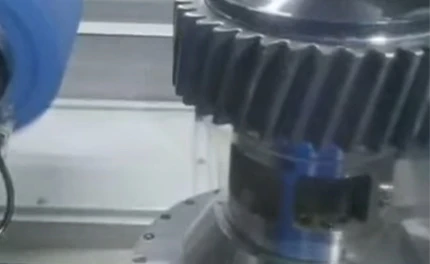

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates