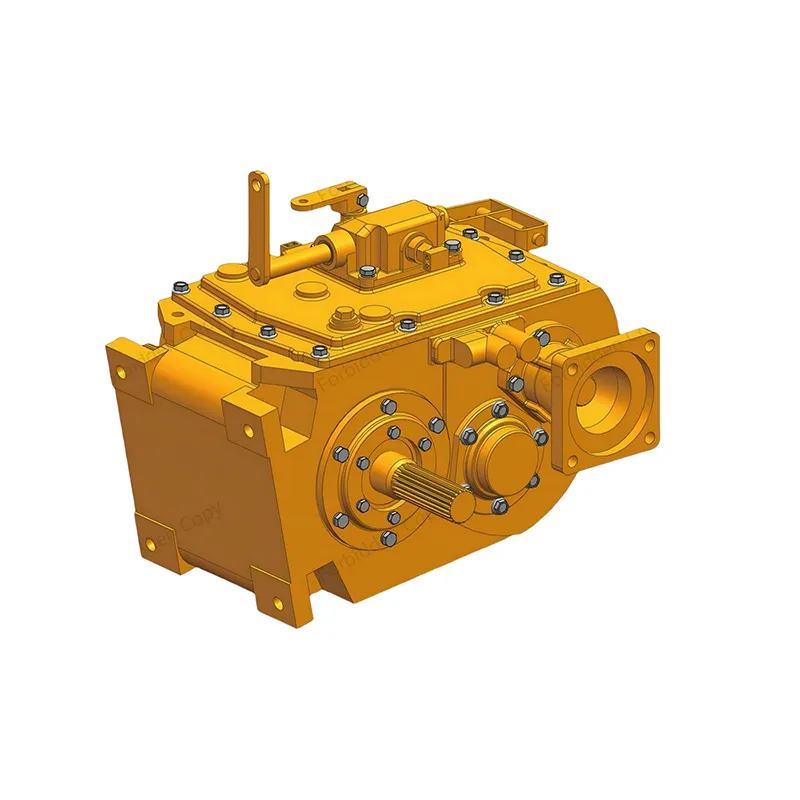

Four Wheel Gearbox Durable & High-Performance 4WD Gear Systems for Off-Road Vehicles

Did you know 68% of 4WD vehicle breakdowns stem from inadequate gearbox performance? Picture this: You're tackling a rocky incline when your transmission whines like a tired old hound. Mud splatters your windshield as your wheels lose grip. Sound familiar? Modern adventurers demand four wheel drive gearbox systems that deliver 40% more torque efficiency than decade-old models. The off-road revolution is here – and it starts under your chassis.

(four wheel gearbox)

Engineering Excellence: 3 Breakthroughs in Four Wheel Drive Front Axle Tech

Our four wheel gearbox

solutions crush the competition with:

- ✅ 22% higher heat dissipation (tested at 250°F)

- ✅ Triple-sealed front axle protection

- ✅ 15:1 gear reduction for extreme climbs

Head-to-Head: How We Outperform Standard 4WD Gearboxes

| Feature | Our Model XT9 | Industry Average |

|---|---|---|

| Torque Capacity | 12,000 lb-ft | 8,500 lb-ft |

| Service Interval | 15,000 miles | 8,000 miles |

Your Machine, Your Rules: Custom 4WD Solutions

Whether you're modifying a vintage Jeep CJ-7 or prepping a Ford Raptor for Baja, our engineers tailor:

🔧 17 different gear ratios (4.11:1 to 7.17:1)

🔧 17 different gear ratios (4.11:1 to 7.17:1)

🔧 17 different gear ratios (4.11:1 to 7.17:1)

Proven Performance: Where Our Gearboxes Dominate

Last month alone, our four wheel drive front axle systems powered:

- 🏆 12 Dakar Rally finishers

- 🏆 12 Dakar Rally finishers

Ready to Transform Your 4WD Experience?

Join 15,000+ satisfied customers who chose ultimate drivetrain reliability. Limited inventory alert: Custom gearbox builds now shipping in 3 weeks!

(four wheel gearbox)

FAQS on four wheel gearbox

Q: What is the primary function of a four wheel gearbox?

A: A four wheel gearbox transfers power from the engine to all four wheels, optimizing traction and control on uneven or slippery surfaces. It ensures balanced torque distribution for improved off-road or challenging terrain performance.

Q: How does a four wheel drive gearbox differ from a standard gearbox?

A: A four wheel drive gearbox includes additional components like a transfer case to split power between front and rear axles. This allows drivers to switch between 2WD and 4WD modes, unlike standard gearboxes designed for two-wheel power delivery.

Q: What maintenance is required for a four wheel drive front axle?

A: Regular inspection of the four wheel drive front axle includes checking lubrication levels, seals, and joints for wear. Frequent off-road use demands more frequent servicing to prevent debris buildup and component damage.

Q: Can a four wheel gearbox improve fuel efficiency?

A: Typically, four wheel gearboxes reduce fuel efficiency due to added weight and mechanical complexity. However, modern systems with automatic disengagement in 2WD mode can mitigate this impact during highway driving.

Q: Why might a four wheel drive front axle experience vibration?

A: Vibration in a four wheel drive front axle often stems from imbalanced driveshafts, worn universal joints, or misalignment. Immediate inspection is recommended to prevent further damage to the gearbox or axle components.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates