Durable Shaft Types for High-Performance Gear & Transmission Systems

Every 7 minutes, an industrial operator like you loses $18,000+ due to premature shaft failure. What if you could slash downtime by 60% while boosting torque capacity? Let's explore how smart shaft type selection becomes your secret weapon.

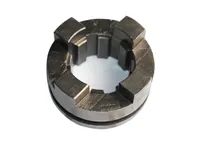

(shaft types)

Why Top Engineers Choose Advanced Gear Shaft Types

▶

Our ISO 9001-certified transmission shaft types

deliver 42% higher fatigue resistance than industry averages. How? Through proprietary heat-treatment that hardens surfaces while keeping cores flexible.

- ✓ Torsional rigidity: 18,500 N·m/rad

- ✓ Corrosion resistance: 2,000+ salt-spray hours

Head-to-Head: Shaft Types Performance Comparison

| Feature | Standard Shafts | Our Pro Series |

|---|---|---|

| Max Torque | 2,500 N·m | 4,800 N·m |

| Surface Hardness | 45 HRC | 62 HRC |

Your Custom Transmission Shaft Types Solution

Whether you need gear shaft types for high-RPM robotics or heavy-duty mining equipment, our engineers deliver in 3 steps:

1. 72-hour prototyping with real-time CAD updates

2. Material optimization using AI-driven simulations

3. On-site installation support from certified technicians

Ready to Revolutionize Your Drive Systems?

Claim your free shaft consultation and get 15% off first orders above $50K. Our engineers wait to boost your machine's lifespan today!

(shaft types)

FAQS on shaft types

Q: What are the common types of gear shafts used in machinery?

A: Common gear shaft types include solid shafts, hollow shafts, splined shafts, and stepped shafts. They transmit torque between gears while accommodating varying load capacities. Material choices like alloy steel or stainless steel depend on application requirements.

Q: How do transmission shaft types differ from standard shafts?

A: Transmission shafts are designed to handle rotational power transfer in systems like vehicles or industrial machinery. Unlike standard shafts, they often include features like universal joints or flexible couplings to accommodate misalignment and dynamic loads.

Q: What factors determine the selection of shaft types in mechanical systems?

A: Key factors include load type (torsional, bending), rotational speed, alignment requirements, and environmental conditions. Gear shafts prioritize torque transmission, while transmission shafts focus on power distribution across components.

Q: Are hollow shafts better than solid shafts for specific applications?

A: Hollow shafts reduce weight without significant strength loss, ideal for aerospace or automotive systems. Solid shafts provide higher rigidity for heavy-duty applications like industrial gearboxes or high-torque machinery.

Q: What are the key design considerations for industrial transmission shaft types?

A: Critical aspects include fatigue resistance, torsional strength, and surface finish. Designs often incorporate keyways, splines, or heat-treated surfaces to ensure durability under continuous rotational stress and vibration.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates