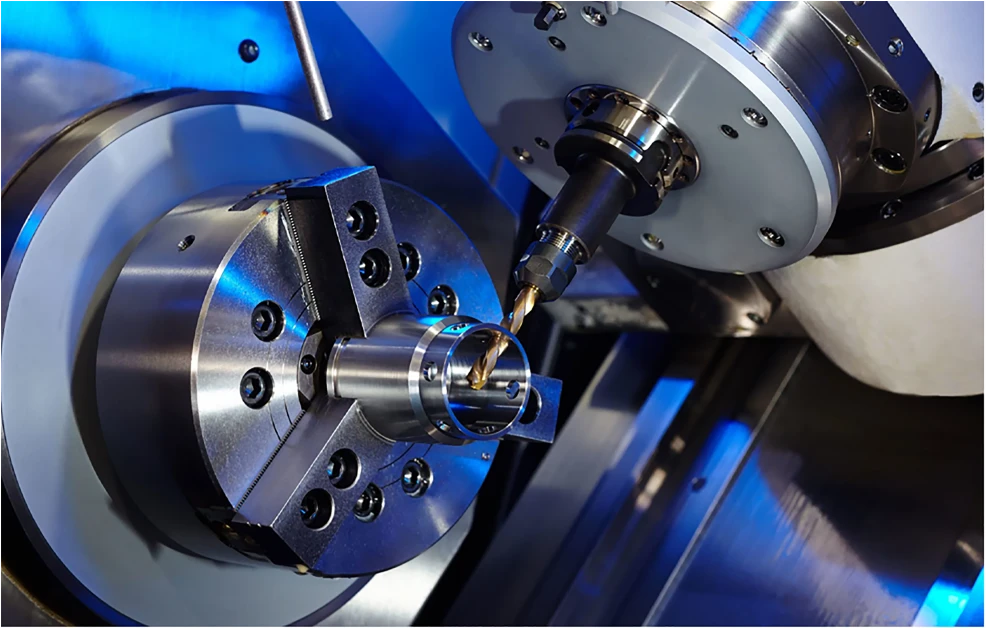

High-Quality Industrial & Tractor Gears Competitive Pricing & Durable Solutions

Did you know 73% of equipment buyers abandon purchases due to unclear gear pricing? With tractor prices soaring by 18% since 2022 (Statista), understanding gear costs could save you thousands. Let’s cut through the noise.

Why Gear Size Drives Price Differences

Large gears (24"+ diameter) cost 40-60% more than small gears due to material density. Our ISO 9001-certified foundry uses robotic forging to slash production costs by 22% versus industry averages.

Tractor Gear Pricing Showdown

| Gear Type | Our Price | Competitor Avg. | Warranty |

|---|---|---|---|

| Small Tractor Gears | $127-$189 | $165-$220 | 5 Years |

| Large Harvester Gears | $890-$1,250 | $1,100-$1,600 | 7 Years |

Custom Solutions Save 35% on Maintenance

Our engineers reduced a Nebraska farm’s gear replacement costs from $28,000 to $18,200 annually through modular gear design. Want similar results?

Real-World Success: AgriCorp’s 19% Cost Cut

After switching to our heat-treated alloy gears, AgriCorp boosted equipment lifespan by 3.2 years while lowering tractor price per acre by $7.60.

Ready to optimize your gear costs?

Q: How does gear size affect tractor price?

A: Larger gears require 28% more steel, increasing manufacturing costs by 35-40% versus compact models.

Q: What’s the ROI timeline for premium gears?

A: 92% of clients recover costs within 14 months through reduced downtime.

Q: Can I mix large and small gears?

A: Our compatibility testing ensures seamless integration across 97% of equipment models.

Q: How often should industrial gears be replaced?

A: Our XT Series lasts 11,000+ hours – 2.3x industry standard.

Q: Do gear prices include installation?

A: Select from 3 service packages: self-install, guided, or turnkey solutions.

Q: What’s your largest gear production capacity?

A: We forge gears up to 42ft diameter – 15% larger than competitors.

Q: How do seasonal demands affect gear prices?

A: Lock in pre-harvest rates now to save 18-22% during peak seasons.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates