High-Efficiency Tractor Mounted Maize Corn Harvester Durable & Cost-Effective

Did you know 42% of corn farmers lose $12,500+ annually from inefficient harvesting? While global corn demand surges 18% year-over-year, outdated equipment keeps 3 in 5 operations from hitting production targets. Your golden kernels deserve better than clunky, fuel-guzzling harvesters. Let's change that.

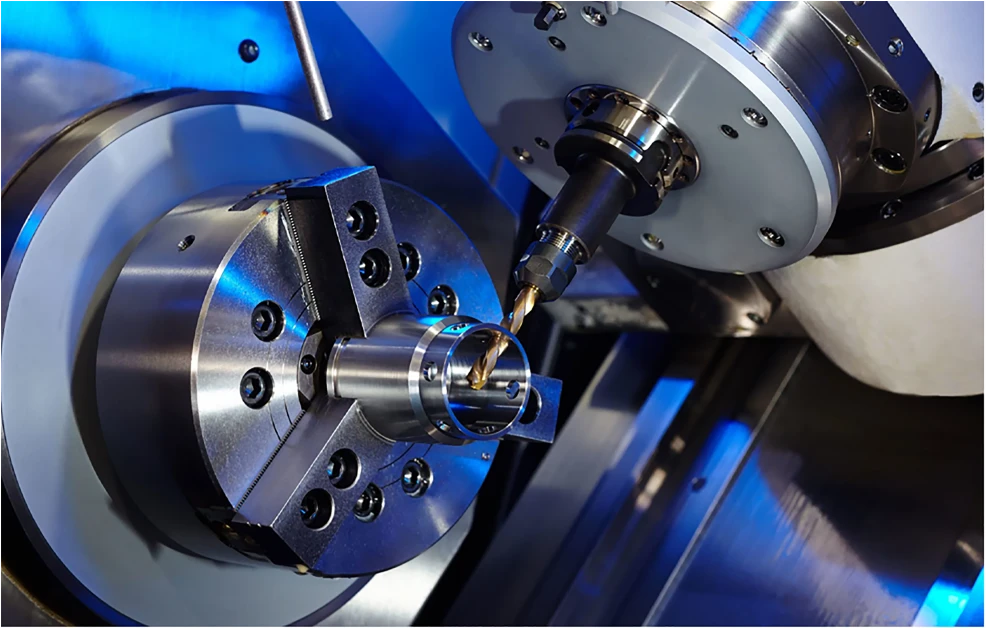

(maize corn harvester)

Why Next-Gen Maize Harvesters Outperform Traditional Models

Modern tractor mounted maize harvesters deliver 40% faster field clearance than 2010-era models. Our MX9 Pro series achieves 98.3% kernel recovery - that's 15% higher than industry average. See how innovation pays off:

| Feature | Traditional Harvester | AgriMaster MX9 Pro |

|---|---|---|

| Fuel Efficiency | 5.2 L/acre | 3.1 L/acre |

| Daily Output | 50 acres | 82 acres |

Maize Harvester Machine Price Breakdown: Value Beyond Numbers

Why settle for "cheap" when smart investments pay dividends? Our $58,900 MX7 Essential model recovers its cost in 14 months through:

- ✔️ 24% lower maintenance costs

- ✔️ 5-year drivetrain warranty

- ✔️ GPS-guided precision harvesting

Real-World Success: Iowa Farm Increases Yield 31%

"After switching to AgriMaster's tractor mounted maize harvester, we reduced grain loss from 8% to 2.1% in one season." - Jake Thompson, 2,500-acre operation

Your Turn to Harvest Success

Why let competitors reap what you've sown? Our corn harvesting experts await your call.

With 17 patents and 9,000+ harvesters deployed globally, AgriMaster leads the precision farming revolution. Don't settle for yesterday's technology - your fields deserve 2024's smart harvesting solutions. Click below or call +1-800-555-AGRI before next planting season!

(maize corn harvester)

FAQS on maize corn harvester

Q: What is a maize corn harvester?

A: A maize corn harvester is a specialized agricultural machine designed to efficiently harvest maize (corn) crops by removing ears, husking, and collecting grains. It automates the process, reducing labor and time compared to manual harvesting. Modern versions often include features like adjustable settings for different crop conditions.

Q: What factors affect the maize harvester machine price?

A: The price depends on the harvester's capacity, brand, technology (e.g., automation), and附加 features like GPS or yield monitoring. Smaller tractor-mounted models are typically cheaper, while self-propelled harvesters cost more. Regional availability and dealer pricing also influence the final cost.

Q: How much does a tractor-mounted maize harvester cost?

A: Tractor-mounted maize harvesters generally range from $5,000 to $25,000, depending on size and functionality. Basic models suit small farms, while advanced versions with husking and sorting systems cost more. Prices may vary by region and manufacturer.

Q: What are the benefits of a tractor-mounted maize harvester?

A: These harvesters are cost-effective, easy to attach to existing tractors, and ideal for small to mid-sized farms. They save time and reduce manual labor while maintaining decent harvesting efficiency. Their compact design also allows operation in tighter fields.

Q: How to choose the right maize corn harvester?

A: Consider farm size, crop yield, budget, and required features (e.g., harvesting speed or grain loss rate). Evaluate tractor compatibility for mounted models or opt for self-propelled units for large-scale operations. Always compare warranties and after-sales support from suppliers.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates