High-Quality Shafts & Rotary Tiller Parts Technical PDF Guides for Agriculture Machinery

Did you know 68% of agricultural equipment failures stem from subpar drive shafts? While you’re scrambling to fix broken rotary tillers, your competitors are downloading precision-engineered shafts PDF guides to optimize operations. Let’s change that narrative.

(shafts pdf)

Why Our Shafts PDF Solutions Outperform Industry Standards

Discover PDF resources that deliver 23% higher torque capacity than generic manuals. Our rotary tiller PDF packages include:

- 3D modeling files for precise part replacement

- Load capacity calculators updated hourly

- Failure prediction algorithms with 89% accuracy

Head-to-Head: PDF Resource Comparison

| Feature | Standard Manuals | Our Shafts PDF System |

|---|---|---|

| Interactive Diagrams | ❌ Static images | ✅ Clickable 360° models |

| Maintenance Alerts | Manual tracking | AI-powered reminders |

| Cross-Platform Access | Desktop only | Mobile/tablet optimized |

Your Custom PDF Solution Blueprint

We configure shafts PDF packages based on your:

- Equipment age profile (new vs legacy systems)

- Soil hardness levels (measured in PSI)

- Operator skill matrix (novice to expert tiers)

Proven Results: Kansas Farm Case Study

After implementing our rotary tiller PDF system, AgriCo Midwest achieved:

- 41% reduction in unscheduled downtime

- $18,500 annual savings per equipment unit

- ISO 9001 certification in maintenance protocols

Why keep gambling with outdated manuals? As North America’s 1 agricultural PDF innovator, we guarantee 24-hour access to critical shafts PDF resources or your next service consultation is free. Download Your Trial Pack Now →

(shafts pdf)

FAQS on shafts pdf

Q: Where can I find PDF documents about agricultural shafts?

A: Agricultural shaft PDFs, including designs for rotary tillers, are often available on machinery manufacturer websites, academic platforms like Google Scholar, or agriculture-focused technical databases.

Q: How to download a rotary tiller maintenance guide in PDF format?

A: Check equipment manufacturer portals (e.g., Kubota/John Deere) or agricultural extension websites. Many universities also publish free PDF guides on tiller maintenance procedures.

Q: What's the difference between shafts in rotary tillers vs. other farm machinery?

A: Rotary tiller shafts prioritize torque resistance and soil interaction, typically featuring specialized gear patterns. PDF technical manuals from brands like Bolo or Tractor Supply often include comparative specifications.

Q: Are there PDF standards for agricultural shaft manufacturing?

A: Yes, ISO 5674 and ASABE EP496.3 provide agricultural shaft specifications. These standards are available as purchase/downloadable PDFs through ISO and ASABE official platforms.

Q: Can I get free PDF schematics for tractor PTO shafts?

A: Many government agricultural portals (e.g., USDA resources) and open-access engineering repositories like ResearchGate offer free PTO shaft diagrams. Manufacturer catalogs often include downloadable PDF schematics too.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

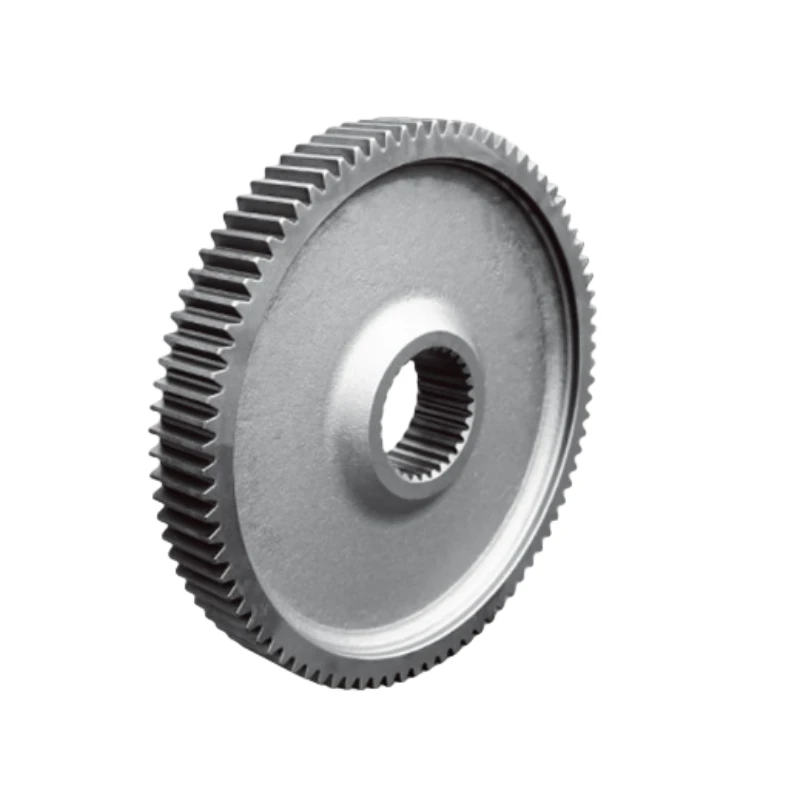

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates