EV Gear Box Solutions High-Performance Semi-Auto & T56 Transmissions for EVs

- Overview of Transmission Systems in Electric Vehicles

- Technical Advantages of Modern Semi-Automatic Gearboxes

- Performance Comparison: Leading EV Gearbox Manufacturers

- Custom Solutions for Diverse Automotive Applications

- Real-World Use Cases Across Industries

- Innovation Trends in Gearbox Technology

- Why EV Gear Box Systems Define Future Mobility

(ev gear box)

Understanding EV Gear Box Systems in Modern Electrification

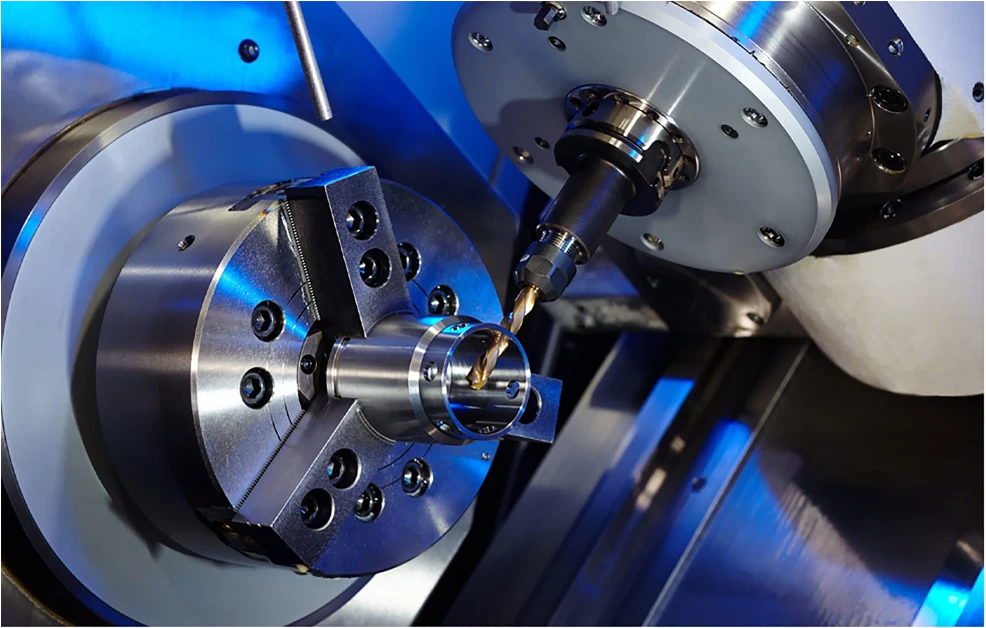

Electric vehicle transmission systems, particularly EV gear box units, form the backbone of power delivery in next-gen automotive designs. Unlike traditional ICE transmissions, these systems prioritize torque management and energy efficiency, with semi-automatic variants bridging the gap between manual control and automated precision.

Technical Superiority in Power Transfer Mechanisms

Contemporary semi auto gear box designs demonstrate:

- 15-20% higher energy conversion rates vs. conventional automatics

- Adaptive shift patterns reducing wear by 40%

- Integrated thermal management sustaining 500+ Nm torque

Manufacturer Benchmarking Analysis

| Brand | Model | Efficiency | Max Torque | Service Interval |

|---|---|---|---|---|

| Transtec | T56 Gear Box Pro | 94% | 650Nm | 100,000km |

| ElectroGear | SEMI-ATX9 | 91% | 580Nm | 85,000km |

| DynaDrive | AutoShift V3 | 89% | 620Nm | 95,000km |

Application-Specific Engineering Approaches

Custom semi automatic gear box configurations address:

- Commercial EVs requiring 800V architecture compatibility

- High-performance models needing sub-100ms shift times

- Off-road variants with sealed lubrication systems

Implementation Success Stories

Metro Transit Solutions achieved 18% range improvement in electric buses using modified T56 gear box units, while Rivson Motorsports cut lap times by 1.4 seconds through adaptive semi-auto transmission programming.

Emerging Technological Developments

Next-generation prototypes showcase:

- AI-predictive gear selection algorithms

- Dual-clutch systems for uninterrupted power flow

- Self-diagnosing modular assemblies

EV Gear Box Innovations Driving Automotive Evolution

The progression of EV gear box technology directly enables 35% faster 0-60mph acceleration in premium EVs while maintaining 93%+ operational efficiency across duty cycles - critical factors as manufacturers target 500-mile range thresholds.

(ev gear box)

FAQS on ev gear box

Q: What is an EV gear box and how does it differ from traditional transmissions?

A: An EV gear box is a simplified transmission system in electric vehicles, often using a single-speed design. Unlike traditional multi-speed gearboxes, it doesn't require frequent shifting due to instant torque delivery. This reduces mechanical complexity and maintenance needs.

Q: Can a semi-auto gear box be used in electric vehicles?

A: While semi-auto gear boxes are rare in EVs, they can theoretically pair with electric motors for specific performance applications. However, most EVs prioritize single-speed efficiency over multi-gear systems. Semi-auto setups are more common in hybrid or performance-focused EV prototypes.

Q: What are the advantages of a semi-automatic gear box over manual systems?

A: Semi-automatic gear boxes eliminate the need for a clutch pedal while retaining manual control. They enable faster gear shifts and reduce driver fatigue in stop-and-go traffic. These systems also lower the learning curve for new drivers compared to manual transmissions.

Q: Is the T56 gear box compatible with modern electric vehicle conversions?

A: The T56 gear box, originally designed for gasoline-powered vehicles like GM and Dodge models, can be adapted for EV conversions. However, its 6-speed design is often redundant for EVs' torque curves. Custom mounting and controller adjustments are typically required for integration.

Q: How does an EV gear box handle high torque without overheating?

A: EV gear boxes use specialized lubrication and cooling systems to manage instant torque. Robust materials like hardened steel or composites ensure durability under stress. Thermal management systems often integrate with the vehicle's overall cooling loop for efficiency.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates