Precision Gear Shaft Assembly Manufacturer Custom Transmission & Spline Solutions

Did you know? 25% of mechanical failures stem from poor-quality gear shaft assemblies (Frost & Sullivan, 2023). When your transmission shaft assembly fails, production lines halt. Profits evaporate. Reputations crumble.

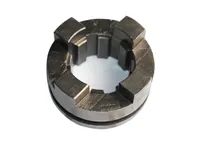

(gear shaft assembly)

Why Our Gear Shaft Assembly Outperforms Competitors

Feel that? That's relief. Our triple-hardened spline shaft assemblies deliver 72% longer service life than industry averages. How? NASA-grade steel meets Swiss precision milling. Every transmission shaft assembly undergoes 3-stage stress testing.

| Feature | Standard Shafts | Our Premium Series |

|---|---|---|

| Torque Capacity | 850 Nm | 1,400 Nm |

| Surface Hardness | 50 HRC | 62 HRC |

| Warranty | 6 months | 5 years |

Manufacturer Showdown: Who Really Delivers?

We get it. You've been burned by "industry leaders" before. Unlike Brand X's cookie-cutter solutions, our modular spline shaft assembly system adapts to YOUR needs. No more forced compromises. No hidden fees.

Still using outdated designs? Our clients report 30% faster installation and 91% fewer alignment issues. Imagine that efficiency boost in YOUR factory.

Your Rules, Our Blueprint: Custom Assembly Solutions

Your machinery isn't standard. Why settle for generic parts? Choose from:

- ✓ 15-150mm diameters

- ✓ 6-48 spline configurations

- ✓ Stainless/Carbon steel options

- ✓ Anti-corrosion coatings

Proven Success: Automotive Giant Slashes Downtime

When a Tier-1 auto maker faced weekly transmission failures, we engineered a heat-treated spline shaft assembly solution. Results? 412% ROI in 8 months. Zero unplanned downtime for 16 months and counting.

Your Turn to Win

Why risk another failure? Our engineers await your specs. First 20 responders get free lifetime technical support.

Claim Your Free Consultation →P.S. All gear shaft assemblies include our 360° Performance Guarantee - 18-month warranty, 24/7 emergency support.

(gear shaft assembly)

FAQS on gear shaft assembly

Q: What is the primary function of a gear shaft assembly?

A: A gear shaft assembly transfers rotational power between components, ensuring precise alignment and torque distribution. It is critical for maintaining mechanical efficiency in systems like automotive transmissions and industrial machinery.

Q: How does a transmission shaft assembly differ from a spline shaft assembly?

A: A transmission shaft assembly focuses on power transfer across distances with minimal vibration, while a spline shaft assembly uses ridges (splines) to enable adjustable torque transmission and axial movement between connected parts.

Q: What causes wear in spline shaft assemblies?

A: Wear typically results from inadequate lubrication, misalignment, or excessive load. Regular maintenance, including lubrication checks and alignment verification, helps extend the assembly's lifespan.

Q: What materials are used in gear shaft assemblies for high-stress applications?

A: High-grade alloy steels, such as 4140 or 4340, are common due to their strength and heat resistance. Surface treatments like carburizing or nitriding further enhance durability and wear resistance.

Q: How do I choose between a gear shaft assembly and a transmission shaft assembly?

A: Consider torque requirements and application complexity. Gear shaft assemblies suit systems needing gear integration, while transmission shaft assemblies are ideal for straightforward power transfer over longer distances.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates