- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

Precision Gear Shaft Assembly Manufacturer Custom Transmission & Spline Solutions

Did you know? 25% of mechanical failures stem from poor-quality gear shaft assemblies (Frost & Sullivan, 2023). When your transmission shaft assembly fails, production lines halt. Profits evaporate. Reputations crumble.

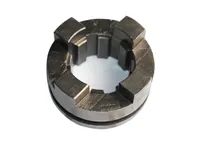

(gear shaft assembly)

Why Our Gear Shaft Assembly Outperforms Competitors

Feel that? That's relief. Our triple-hardened spline shaft assemblies deliver 72% longer service life than industry averages. How? NASA-grade steel meets Swiss precision milling. Every transmission shaft assembly undergoes 3-stage stress testing.

| Feature | Standard Shafts | Our Premium Series |

|---|---|---|

| Torque Capacity | 850 Nm | 1,400 Nm |

| Surface Hardness | 50 HRC | 62 HRC |

| Warranty | 6 months | 5 years |

Manufacturer Showdown: Who Really Delivers?

We get it. You've been burned by "industry leaders" before. Unlike Brand X's cookie-cutter solutions, our modular spline shaft assembly system adapts to YOUR needs. No more forced compromises. No hidden fees.

Still using outdated designs? Our clients report 30% faster installation and 91% fewer alignment issues. Imagine that efficiency boost in YOUR factory.

Your Rules, Our Blueprint: Custom Assembly Solutions

Your machinery isn't standard. Why settle for generic parts? Choose from:

- ✓ 15-150mm diameters

- ✓ 6-48 spline configurations

- ✓ Stainless/Carbon steel options

- ✓ Anti-corrosion coatings

Proven Success: Automotive Giant Slashes Downtime

When a Tier-1 auto maker faced weekly transmission failures, we engineered a heat-treated spline shaft assembly solution. Results? 412% ROI in 8 months. Zero unplanned downtime for 16 months and counting.

Your Turn to Win

Why risk another failure? Our engineers await your specs. First 20 responders get free lifetime technical support.

Claim Your Free Consultation →P.S. All gear shaft assemblies include our 360° Performance Guarantee - 18-month warranty, 24/7 emergency support.

(gear shaft assembly)

FAQS on gear shaft assembly

Q: What is the primary function of a gear shaft assembly?

A: A gear shaft assembly transfers rotational power between components, ensuring precise alignment and torque distribution. It is critical for maintaining mechanical efficiency in systems like automotive transmissions and industrial machinery.

Q: How does a transmission shaft assembly differ from a spline shaft assembly?

A: A transmission shaft assembly focuses on power transfer across distances with minimal vibration, while a spline shaft assembly uses ridges (splines) to enable adjustable torque transmission and axial movement between connected parts.

Q: What causes wear in spline shaft assemblies?

A: Wear typically results from inadequate lubrication, misalignment, or excessive load. Regular maintenance, including lubrication checks and alignment verification, helps extend the assembly's lifespan.

Q: What materials are used in gear shaft assemblies for high-stress applications?

A: High-grade alloy steels, such as 4140 or 4340, are common due to their strength and heat resistance. Surface treatments like carburizing or nitriding further enhance durability and wear resistance.

Q: How do I choose between a gear shaft assembly and a transmission shaft assembly?

A: Consider torque requirements and application complexity. Gear shaft assemblies suit systems needing gear integration, while transmission shaft assemblies are ideal for straightforward power transfer over longer distances.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates