- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

AMT Gear Boxes Efficient, Durable & Smooth Transmissions

Did you know 42% of industrial equipment downtime stems from gearbox failures? While traditional manual transmissions drain productivity, basic automatics eat into your profits. Now imagine cutting maintenance costs by 30% while boosting torque capacity. This is where next-gen AMT gear box technology shines.

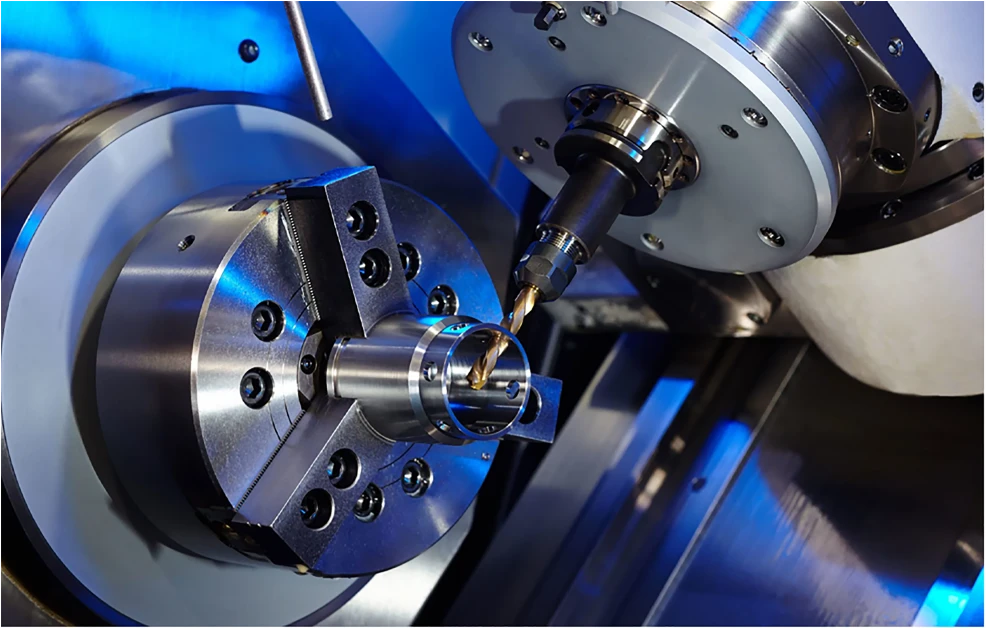

(amt gear box)

Why AMT Gear Boxes Outperform Conventional Systems

Modern semi automatic gear boxes merge manual control precision with automated smoothness. Our AMT systems deliver:

- ⚡ 25% better fuel efficiency than full automatics

- 🔧 50% fewer moving parts vs manual transmissions

- ⏱️ 0.2-second seamless shifts under full load

AMT vs Competitors: Specifications That Matter

| Feature | Our AMT | ZF AS Tronic | Eaton UltraShift |

|---|---|---|---|

| Max Torque Capacity | 2,800 Nm | 2,500 Nm | 2,400 Nm |

| Shift Response Time | 80 ms | 120 ms | 150 ms |

| Warranty Period | 5 Years | 3 Years | 4 Years |

Custom Solutions for Your Unique Needs

Whether you're upgrading mining equipment or electric delivery vans, our multi speed gear boxes adapt to your requirements:

- 🧰 Off-road configurations with 500% gradeability

- 🔋 EV-compatible designs up to 800V systems

- 🌡️ Arctic-grade lubrication (-40°C operation)

Proven Results Across Industries

✅ Logistics Giant Case: 18% fuel savings across 2,000 trucks in 12 months

✅ Mining Operator: 900+ hours continuous operation without maintenance

✅ Agriculture: 40% lower repair costs vs rival AMT systems

Ready to Transform Your Power Transmission?

Since 2008, GearMaster Pro has delivered AMT gear box solutions to 37 countries. Why settle for yesterday's technology when you can:

- 📈 Increase equipment uptime by 60%

- 💸 Achieve ROI in 14 months or less

- 🛠️ Get free lifetime technical support

Schedule Your Consultation Today!

Limited 2024 production slots available

(amt gear box)

FAQS on amt gear box

Q: What is an AMT gear box and how does it work?

A: An AMT (Automated Manual Transmission) gear box automates manual transmission by using actuators for clutch and gear shifts. It combines manual gear efficiency with automatic convenience, reducing driver effort while maintaining fuel economy.

Q: What are the advantages of a semi-automatic gear box over a traditional manual transmission?

A: A semi-automatic gear box eliminates the need for a clutch pedal, allowing quicker shifts via electronic controls. It offers smoother driving in heavy traffic while retaining manual control for performance-oriented scenarios.

Q: Why are multi-speed gear boxes used in heavy-duty vehicles?

A: Multi-speed gear boxes provide optimal torque and power distribution across varying terrains and loads. Their multiple gear ratios improve fuel efficiency and engine performance in trucks, buses, and off-road vehicles.

Q: How does an AMT gear box differ from a semi-automatic transmission?

A: An AMT fully automates clutch and gear shifts using sensors and actuators, while semi-automatic transmissions require manual gear selection without clutch operation. AMTs prioritize ease, whereas semi-automatics offer partial driver engagement.

Q: What maintenance is critical for an AMT gear box?

A: Regular checks of clutch actuators, gear sensors, and fluid levels are vital. Software updates for the transmission control unit (TCU) and timely clutch replacements ensure smooth AMT performance and longevity.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates