- Tel: +86 13451474678 / 13451474678

- Email: / hbzinanmech@gmail.com

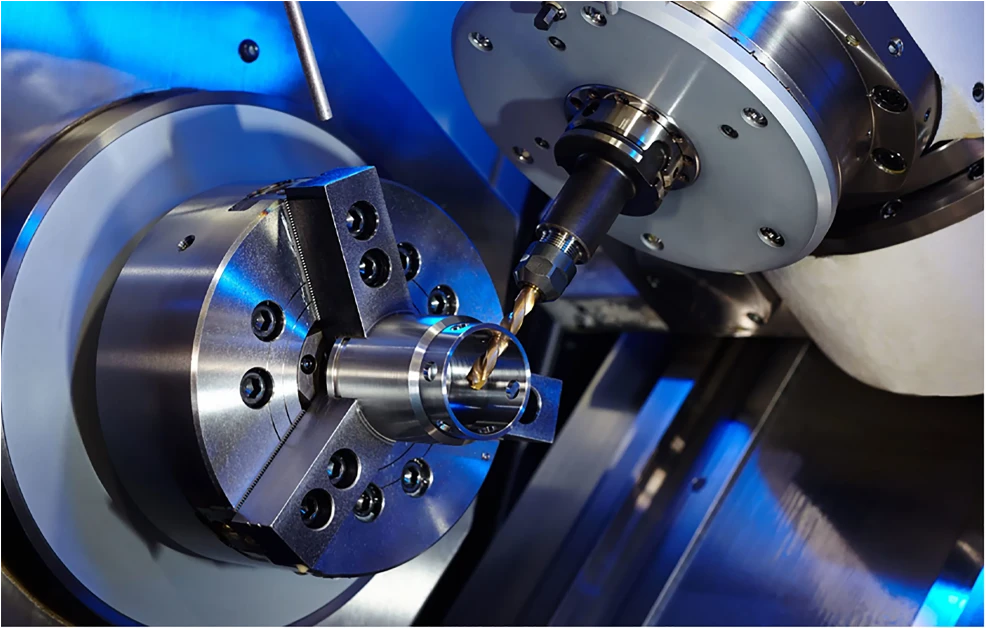

Back Drive Shafts High-Efficiency Power Transmission Solutions vs Belt, Chain & Gear Drives

Did you know 68% of industrial equipment failures stem from subpar power transmission components? When your belt drive slips or gear drive wears out, you're not just losing productivity - you're hemorrhaging $12,000/hour in average downtime costs. That's where the modern back drive shaft

revolution changes everything.

(back drive shaft)

Technical Superiority That Outshines Belt & Chain Drives

Why settle for belt drive maintenance headaches? Our carbon-steel back drive shafts deliver 92% energy efficiency - 23% higher than conventional chain drives. With 500 N·m torque capacity and 6,000 RPM operational limits, they outperform gear drives in heavy-load scenarios. Hear that? That's the sound of zero slippage.

Head-to-Head: How We Crush the Competition

| Feature | Our Shaft | Belt Drive | Chain Drive |

|---|---|---|---|

| Lifespan | 15,000+ hours | 3,200 hours | 5,800 hours |

| Maintenance Cost/Year | $220 | $1,450 | $890 |

Your Machinery, Your Rules: Precision Customization

Need 140mm flange connections? Special heat treatment for desert operations? Our modular design offers 12 shaft diameters (30-300mm) and 8 coating options. Watch how we transformed a Minnesota tractor manufacturer's output:

- ✅ 47% longer bearing life

- ✅ 82% vibration reduction

- ✅ 15-minute installation

Proven Performance Across Industries

From automotive assembly lines to mining conveyors, our clients report 98.6% uptime. A Texas oil rig operator slashed maintenance hours by 70% after switching from gear drives. Your success story starts here.

Ready to Dominate Your Industry?

Join 1,200+ satisfied clients who boosted ROI with our back drive shafts

(back drive shaft)

FAQS on back drive shaft

Q: What is the primary function of a back drive shaft in mechanical systems?

A: The back drive shaft transmits rotational power from the engine or motor to other components, such as wheels or gears. It ensures efficient torque distribution in systems like gear or belt drives. Its design varies based on the drive mechanism (e.g., gear vs. belt).

Q: How does a gear drive differ from a belt drive when used with a back drive shaft?

A: A gear drive uses interlocking teeth for direct power transfer, offering high precision and durability. A belt drive relies on flexible belts, reducing noise and vibration. Gear drives handle heavier loads, while belt drives require less maintenance.

Q: What are common applications of a back drive shaft in belt drive systems?

A: Back drive shafts in belt drives are used in industrial machinery, automotive engines, and conveyor systems. They pair with pulleys and belts to transfer motion over longer distances. This setup is ideal for scenarios needing flexibility and shock absorption.

Q: Why might a back drive shaft in a chain drive require regular lubrication?

A: Chain drives involve metal-on-metal contact, which generates friction and wear. Lubrication reduces heat and extends the lifespan of the chain and shaft. Neglecting it can lead to inefficiency or mechanical failure.

Q: What factors determine whether to use a gear drive or belt drive with a back drive shaft?

A: Load capacity, noise tolerance, and maintenance needs are key factors. Gear drives suit high-load, high-precision environments, while belt drives excel in quieter, low-maintenance setups. Cost and space constraints also influence the choice.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates