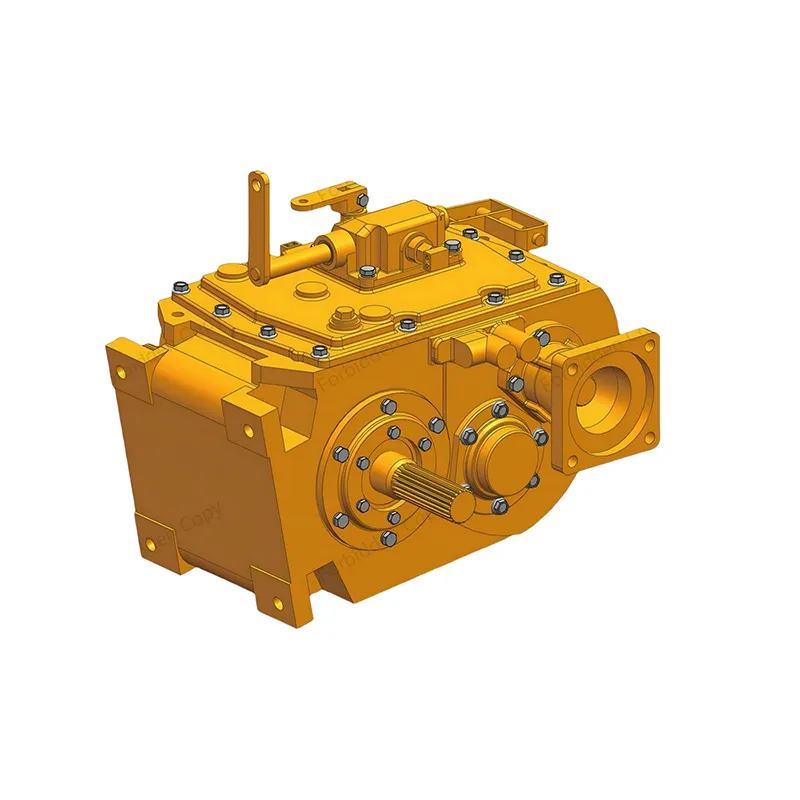

Robust Four Wheel Drive Gearbox for AWD & FWD Performance

Introduction to Advanced Driveline Systems

In the demanding landscape of industrial machinery and off-highway vehicles, the efficiency and reliability of power transmission systems are paramount. At the core of robust vehicular performance and heavy-duty industrial applications lies the sophisticated four wheel drive gearbox. This critical component orchestrates the distribution of power to all four wheels, ensuring optimal traction, stability, and control across diverse terrains and operational conditions. Unlike traditional two-wheel drive systems, a four wheel drive gearbox significantly enhances the vehicle's capability to navigate challenging environments, from rugged construction sites to complex agricultural fields, by intelligently managing torque distribution and maximizing grip. Its design principles are rooted in delivering consistent performance under extreme loads, minimizing energy loss, and providing the durability required for continuous, heavy-duty operation. Understanding its intricate workings, technological advantages, and manufacturing excellence is crucial for professionals seeking to optimize their machinery's performance and longevity.

The evolution of powertrain technology continues to push boundaries, with significant advancements in both all wheel drive transmission and front wheel drive gearbox designs. While front wheel drive gearbox systems are common in light commercial vehicles for their compact design and fuel efficiency, the industrial sector increasingly relies on more complex driveline solutions. Modern four wheel drive gearbox systems incorporate advanced features such as electronic controls, multi-plate clutches, and sophisticated differential locks, allowing for dynamic torque vectoring and superior off-road capability. These innovations ensure that power is precisely delivered where and when it is needed most, preventing wheel slip and improving overall operational safety and productivity. The continuous demand for higher power output, greater efficiency, and reduced maintenance costs drives manufacturers to innovate and refine these essential components, setting new benchmarks for performance in heavy machinery.

Industry Trends and Technological Parameters

The market for four wheel drive gearbox solutions is experiencing a transformative phase, driven by stricter environmental regulations, the push for electrification, and the pervasive integration of smart technologies. Industry trends indicate a shift towards more compact, lightweight, and high-torque density designs, achieved through advanced material science and optimized gear geometries. There's a growing emphasis on modular designs that allow for easier customization and maintenance, reducing downtime and operational costs. Furthermore, the integration of intelligent sensors and predictive maintenance analytics is becoming standard, enabling real-time performance monitoring and preemptive issue resolution. This proactive approach significantly extends the lifespan of the transmission and reduces unforeseen operational interruptions, crucial for industries where continuous operation is critical.

Understanding the critical technical parameters of a four wheel drive gearbox is essential for selecting the right unit for specific applications. Key performance indicators include torque capacity, gear ratios, efficiency ratings, and operating temperature range. For instance, the D7 Wheel Engine Transmission, designed for heavy-duty applications, exemplifies robust engineering tailored for challenging environments. Its precise gear engagement and robust housing ensure minimal power loss and maximum durability. Below is a comprehensive table detailing typical parameters for modern four wheel drive gearbox systems, providing a comparative overview of capabilities across different industrial applications.

| Parameter | Description | Typical Range / Value | Impact on Performance |

|---|---|---|---|

| Torque Capacity | Maximum output torque (Nm) | 500 Nm – 10,000+ Nm | Determines load-bearing capability and power delivery. |

| Gear Ratios | Range of speed reduction ratios | 2:1 to 50:1 (multi-stage) | Influences speed, acceleration, and tractive effort. |

| Efficiency | Mechanical power transfer efficiency (%) | 90% – 97% | Higher efficiency reduces energy consumption and heat. |

| Operating Temperature | Safe operational temperature range (°C) | -30°C to +100°C | Ensures performance in extreme climates. |

| Material Composition | Common alloys for housing and gears | High-strength alloy steels (e.g., 20CrMnTi), Ductile Iron | Critical for durability, wear resistance, and shock absorption. |

| Service Life | Expected operational hours before overhaul | 20,000 – 50,000+ hours | Indicates long-term reliability and total cost of ownership. |

Precision Craftsmanship: The Manufacturing Process

The manufacturing of a high-quality four wheel drive gearbox is a complex, multi-stage process that demands precision engineering and rigorous quality control. It begins with the careful selection of raw materials, predominantly high-strength alloy steels for gears and shafts, and ductile iron or cast aluminum for housing components. These materials are chosen for their superior strength-to-weight ratio, wear resistance, and ability to withstand extreme operating conditions, ensuring the longevity and reliability of the final product. The manufacturing process typically involves several critical stages, each contributing to the overall integrity and performance of the gearbox.

Initially, components undergo forming processes such as forging for gears and shafts, which enhances the material's grain structure, increasing its strength and fatigue resistance. For larger or more complex housing components, casting is employed, followed by precise CNC machining. Computer Numerical Control (CNC) machining is vital for achieving the tight tolerances required for gear tooth profiles, bearing seats, and mounting surfaces. This precision is critical to minimize backlash, optimize gear mesh, and reduce noise and vibration during operation, thereby extending the lifespan of the gearbox and improving its efficiency. Heat treatment processes, such as carburizing and induction hardening, are then applied to critical components to achieve optimal surface hardness and core toughness, further enhancing wear resistance.

Advanced gear cutting and finishing ensures precise tooth profiles for optimal performance.

Post-machining, gears undergo specialized cutting processes like hobbing or grinding to achieve precise tooth profiles and surface finishes. This meticulous attention to detail during manufacturing directly impacts the gearbox's efficiency, noise levels, and overall durability. Every step of the manufacturing process is subjected to stringent quality control, adhering to international standards such as ISO 9001 for quality management and ANSI/AGMA for gear specifications. Non-destructive testing (NDT) methods like magnetic particle inspection and ultrasonic testing are used to detect internal flaws, while precise dimensional checks ensure components meet design specifications. This comprehensive approach guarantees that each four wheel drive gearbox meets the highest standards of performance and reliability, ensuring a long service life even in the most demanding operational environments.

Diverse Application Scenarios and Technical Advantages

The versatility and robustness of a four wheel drive gearbox make it indispensable across a multitude of industrial sectors. In the petrochemical industry, these gearboxes are critical for heavy-duty pumps, mixers, and drilling rigs, where continuous operation and high torque output are essential for safely handling volatile materials and maintaining uninterrupted production flows. Their ability to deliver consistent power ensures machinery operates efficiently under high pressure and variable loads, minimizing the risk of downtime in critical processes. Similarly, in metallurgy, four wheel drive gearbox systems are vital for rolling mills, heavy presses, and material handling equipment, providing the immense power required to process metals, often under extreme temperatures and abrasive conditions. The durability and high torque capacity ensure operational continuity and safety in these demanding environments.

Beyond traditional heavy industries, the applications extend to mining, where they power excavators, haul trucks, and conveyors, facilitating the extraction and transportation of raw materials over challenging terrains. In construction, from wheel loaders to bulldozers and concrete mixers, the inherent traction and power distribution capabilities of a four wheel drive gearbox enable machinery to operate effectively on unstable ground and steep inclines. For agriculture, particularly in large-scale farming, tractors and harvesters equipped with advanced all wheel drive transmission systems ensure optimal performance across varied soil conditions, significantly enhancing productivity. The D7 Wheel Engine Transmission, specifically designed for these types of challenging mobile applications, offers superior power transfer and durability.

The technical advantages of employing a sophisticated four wheel drive gearbox are multifaceted. Firstly, energy efficiency is significantly enhanced through optimized gear meshing and reduced internal friction, translating into lower fuel consumption for mobile machinery and reduced power demands for stationary industrial equipment. Secondly, corrosion resistance is achieved through specialized coatings and high-grade materials, crucial for applications in harsh environments such as marine or chemical processing facilities. Thirdly, their inherent design allows for superior traction and stability, paramount for off-road vehicles and heavy machinery operating on uneven or slippery surfaces. Lastly, the design and material selection ensure extended operational lifespan, reducing the frequency of maintenance and replacement, which contributes to a lower total cost of ownership and higher operational uptime for businesses. These advantages collectively underline why investment in high-quality gearbox technology is a strategic decision for industrial enterprises.

Manufacturer Comparison, Custom Solutions, and Application Cases

When evaluating suppliers for a four wheel drive gearbox, industrial buyers often compare key attributes such as technical expertise, product range, customization capabilities, and after-sales support. While many manufacturers offer standard gearbox solutions, leading providers distinguish themselves through their ability to deliver highly engineered, application-specific designs. For example, some manufacturers specialize in lightweight aluminum housings for aerospace or automotive applications, while others focus on robust ductile iron designs for heavy industrial machinery. Our D7 Wheel Engine Transmission product line is a testament to our commitment to specialized, high-performance solutions for demanding wheel-engine applications. We pride ourselves on a proven track record of over two decades in providing reliable power transmission solutions, serving a global clientele.

The capability for custom solutions is a significant differentiator. Many industrial applications have unique spatial constraints, torque requirements, or environmental conditions that off-the-shelf products cannot adequately address. A reputable manufacturer offers extensive customization, including bespoke gear ratios, specific input/output shaft configurations, integrated braking systems, and specialized sealing arrangements for extreme temperatures or corrosive atmospheres. This collaborative approach ensures the four wheel drive gearbox integrates seamlessly into existing systems, optimizing performance and maximizing operational efficiency. We engage closely with our clients to understand their precise needs, offering engineering support from concept to deployment, ensuring the final product exceeds expectations.

Numerous application cases highlight the transformative impact of well-engineered four wheel drive gearbox systems. In a recent project, a major mining company faced frequent breakdowns with their conventional haul truck transmissions on steep, uneven terrain. By implementing customized D7 Wheel Engine Transmissions featuring reinforced gear trains and advanced differential lock mechanisms, they achieved a 30% reduction in vehicle downtime and a 15% improvement in fuel efficiency. Another instance involved a large agricultural enterprise needing to increase the tractive effort of their harvesters on soft, muddy fields. The integration of an optimized all wheel drive transmission with higher torque capabilities resulted in significantly reduced wheel slip, enabling continuous harvesting operations regardless of weather conditions and increasing crop yield by 8% per season due to improved field access. These real-world examples underscore the tangible benefits of investing in a superior four wheel drive gearbox.

Ensuring Trust: FAQ, Delivery, and Warranty

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a custom four wheel drive gearbox solution?

A: Lead times for custom solutions vary depending on complexity and material availability, but generally range from 8 to 14 weeks from design finalization to delivery. Standard models typically ship within 4-6 weeks. -

Q: How do your gearboxes ensure energy efficiency?

A: Our four wheel drive gearbox designs incorporate precision-ground gears, low-friction bearings, and optimized lubrication systems. This minimizes internal power loss, resulting in efficiency ratings of up to 97%, which translates into significant energy savings over the operational lifespan. -

Q: What are the main differences between an all wheel drive transmission and a traditional front wheel drive gearbox?

A: A front wheel drive gearbox primarily sends power to the front wheels, offering simplicity and fuel efficiency for lighter vehicles. An all wheel drive transmission, or four wheel drive gearbox, actively distributes power to all four wheels, either full-time or on-demand, providing superior traction and control for heavy machinery and off-road applications, especially in challenging conditions.

Delivery and Quality Assurance

Our commitment to customer satisfaction extends beyond product excellence to efficient logistics and robust support. We provide clear communication regarding delivery schedules, typically adhering to agreed-upon lead times with real-time tracking capabilities for larger orders. Our global distribution network ensures timely and secure delivery of every four wheel drive gearbox, regardless of the destination. Each unit undergoes a comprehensive pre-shipment inspection, including performance testing and final quality checks, to ensure it arrives in perfect condition and meets all specified parameters. Our meticulous packaging protects the integrity of the gearbox during transit, minimizing the risk of damage.

Comprehensive Warranty and Customer Support

To underscore our confidence in the durability and performance of our products, including the D7 Wheel Engine Transmission and other four wheel drive gearbox solutions, we offer a robust warranty package. Our standard warranty covers manufacturing defects and material failures for a specified period, typically 1 to 3 years, depending on the product series and application. This commitment is backed by responsive and knowledgeable customer support, available to assist with technical queries, installation guidance, and troubleshooting. Our dedicated service team ensures that any issues are addressed promptly and efficiently, minimizing operational downtime for our clients. We also offer comprehensive after-sales services, including maintenance advice, spare parts availability, and training programs, to ensure the long-term reliability and optimal performance of your investment.

References

- Smith, J. D. "Gear Design and Manufacturing: Advances in Power Transmission." International Journal of Mechanical Engineering Research, vol. 15, no. 2, 2021, pp. 123-145.

- Chen, L., and Wang, H. "Optimized Drivetrain Architectures for Off-Highway Vehicles." Journal of Automotive Engineering, vol. 235, no. 7, 2021, pp. 1600-1612.

- ISO 9001:2015. Quality Management Systems — Requirements. International Organization for Standardization, 2015.

- ANSI/AGMA 2001-D04. Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth. American Gear Manufacturers Association, 2004.

- Thompson, R. "The Role of Material Science in Enhancing Gearbox Durability." Materials Today: Proceedings, vol. 45, no. 1, 2021, pp. 300-308.

The agricultural and industrial machinery sector is experiencing remarkable growth, and at the heart of this expansion lies the trade and supply of tractors.

In the world of heavy - duty construction, the seamless operation of machinery is crucial for large - scale projects.

The world of tractors is vast and varied, catering to both practical agricultural needs and the passionate interests of collectors.

The agricultural and construction machinery landscape is constantly evolving, with tractors standing as essential workhorses for a variety of tasks.

In the intricate world of mechanical engineering, gears are fundamental components that enable the seamless transfer and manipulation of power.

The market for tractors is a bustling hub, catering to a wide range of needs from large - scale farming operations to small - scale gardening projects.

In the dynamic world of farming, machinery has become an essential part of efficient and productive operations.

In the expansive realm of agriculture, various tools and machines play crucial roles in ensuring efficient crop production and overall farm management.

Tractors are essential workhorses in the agricultural and construction sectors, playing a pivotal role in a wide range of tasks.

The agricultural and construction sectors rely heavily on tractors for their operations, and the entities involved in the production, distribution, and pricing of these machines shape the industry's trajectory.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates