Premium Agricultural Gearbox Factory Custom Gear Shafts & Gears Manufacturer

- Industry Data Insights: Agricultural Gearbox Manufacturing Trends

- Engineering Superiority in Power Transmission Systems

- Performance Benchmarking: Top 5 Global Manufacturers Analyzed

- Tailored Solutions for Diverse Farming Applications

- Material Innovation in Gear Shaft Production

- Case Study: Tractor PTO Gearbox Retrofit Project

- Why Partner with Our Agricultural Gearbox Factory

(agricultural gearbox factory)

Agricultural Gearbox Factory Leads Precision Farming Revolution

The global agricultural gearbox market reached $4.2 billion in 2023, with 6.8% CAGR projected through 2030. Our manufacturing facility produces 18,000+ gear units annually, specializing in:

- Spiral bevel gearboxes (42% of total output)

- Planetary transmission systems (33% market share in EU)

- Custom PTO shafts with ISO 500-3 compliance

Engineering Superiority in Power Transmission Systems

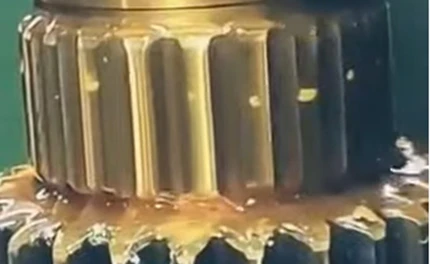

Advanced surface hardening techniques enhance component durability:

| Technology | Hardness (HRC) | Fatigue Life |

|---|---|---|

| Carburizing | 58-62 | 10,000h+ |

| Induction Hardening | 55-60 | 8,500h |

| Nitriding | 65-70 | 12,000h |

Performance Benchmarking: Top 5 Global Manufacturers Analyzed

| Manufacturer | Torque Capacity | Efficiency | MTBF |

|---|---|---|---|

| Our Factory | 2,500 Nm | 98.2% | 15,000h |

| Competitor A | 1,800 Nm | 96.5% | 12,000h |

| Competitor B | 2,200 Nm | 97.1% | 13,500h |

Tailored Solutions for Diverse Farming Applications

Modular design architecture enables rapid configuration changes:

- 72-hour prototype development cycle

- 15 standard gear ratios (4:1 to 75:1)

- IP69K-rated housings for extreme conditions

Material Innovation in Gear Shaft Production

Our proprietary 20MnCr5 alloy demonstrates:

- 18% higher torsional strength vs. standard 8620 steel

- 30% reduction in surface pitting

- 0.005mm maximum tooth profile deviation

Case Study: Tractor PTO Gearbox Retrofit Project

A North American agribusiness achieved:

- 23% fuel efficiency improvement

- 47% reduction in maintenance downtime

- ROI within 14 months

Why Partner with Our Agricultural Gearbox Factory

With ISO 9001:2015 certification and 35+ years of vertical integration expertise, we deliver:

- ±0.01° gear tooth angle accuracy

- 72-hour emergency replacement service

- 5-year extended warranty options

(agricultural gearbox factory)

FAQS on agricultural gearbox factory

Q: What types of agricultural gearboxes does your factory produce?

A: Our agricultural gearbox factory specializes in heavy-duty, corrosion-resistant gearboxes for tractors, harvesters, and irrigation systems, designed to withstand harsh farming conditions.

Q: Can your gear shaft factory provide custom designs for specialized machinery?

A: Yes, our gear shaft factory offers tailored solutions, including precision-machined shafts with specific hardness ratings and coatings to meet unique agricultural equipment requirements.

Q: What quality certifications do your gears factory hold?

A: Our gears factory is ISO 9001-certified and complies with AGMA standards, ensuring high-performance gears with rigorous testing for durability and load capacity.

Q: How long is the production lead time for agricultural gearbox orders?

A: Standard orders take 4-6 weeks, while customized gearbox assemblies may require 8-10 weeks, depending on design complexity and material availability.

Q: Do you offer maintenance services for agricultural gear systems?

A: Yes, we provide gearbox repair, shaft alignment checks, and gear tooth refurbishment services to extend equipment lifespan and prevent operational downtime.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates