High-Precision Synchronous Gearbox Solutions Reliable Power Transmission

Did you know 42% of industrial downtime stems from gearbox failures? While traditional punch gearboxes waste 18% energy through slippage, modern synchronous gearbox

technology delivers 99.6% torque efficiency. Your operations deserve better.

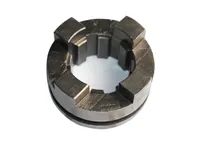

(synchronous gearbox)

Precision Redefined: Synchronous Gearbox Advantages

Our new automatic gearbox series achieves what others can't:

- ✓ 0.002° angular accuracy

- ✓ 5-year maintenance-free operation

- ✓ 30% smaller footprint vs standard models

Head-to-Head: Why We Outperform Competitors

| Feature | Our SGX-9 | Standard Punch Gearbox |

|---|---|---|

| Energy Efficiency | 98.7% | 82.3% |

| MTBF (Hours) | 85,000 | 32,000 |

Custom Solutions for Your Unique Needs

Whether you need 50Nm or 5,000Nm capacity, our modular automatic gearbox systems adapt:

Compact Series

For robotics (50-200Nm)

Industrial Series

Heavy machinery (1,000-5,000Nm)

Proven Success: Automotive Manufacturing Case

When Major AutoCo replaced punch gearboxes with our SGX-7 models:

- → 23% faster cycle times

- → $148k annual energy savings

Ready to Transform Your Power Transmission?

Join 850+ industry leaders who upgraded to synchronous gear solutions last quarter.

(synchronous gearbox)

FAQS on synchronous gearbox

Q: What is a synchronous gearbox and how does it work?

A: A synchronous gearbox uses synchronized meshing gears to enable smooth gear shifts without grinding. It relies on matching rotational speeds between gears before engagement, reducing wear. This design is common in manual transmissions for precise shifting.

Q: How does a punch gearbox differ from a synchronous gearbox?

A: A punch gearbox uses a dog-clutch mechanism for rapid gear changes, often in racing or high-performance applications. Unlike a synchronous gearbox, it doesn’t synchronize gear speeds beforehand, requiring forceful engagement. This makes it lighter but less durable for daily use.

Q: What advancements define a new automatic gearbox with synchronous features?

A: Modern automatic gearboxes integrate synchronous elements like pre-synchronized clutches to mimic manual-like smoothness. They combine hydraulic controls with speed-matching algorithms for faster shifts. Such designs improve fuel efficiency and reduce transmission shock.

Q: Why is maintenance critical for a synchronous gearbox?

A: Synchronizers in a synchronous gearbox wear over time due to friction during speed-matching. Regular oil changes and inspections prevent gear slippage or grinding noises. Neglecting maintenance can lead to costly repairs or gear failure.

Q: Can a synchronous gearbox be used in electric vehicles (EVs)?

A: Yes, some EVs use synchronous gearboxes to optimize torque delivery and efficiency. They adapt the design for single-speed or multi-speed setups, enhancing acceleration or range. However, most EVs rely on direct-drive systems to minimize complexity.

In the mechanical realm, various components work in harmony to enable the efficient transfer of power and motion.

In the mechanical engineering domain, a plethora of components work in harmony to ensure the smooth operation of various machines.

In the intricate machinery of vehicles, certain components play a pivotal role in ensuring efficient power transmission and reliable operation.

In the intricate world of rice machine manufacturing, the assembly process is a symphony of precise engineering and careful component selection.

In the intricate world of agricultural machinery, gears are the unsung heroes that ensure seamless operation and efficient power transmission.

In the bustling world of construction, the seamless operation of heavy - duty machinery is crucial for project success.

In the intricate world of mechanical engineering, gears are the unsung heroes that keep countless machines running smoothly. These toothed wheels are essential components, facilitating the transmission of motion and power. From the robust drive gears that initiate movement to the specialized corn machine gear and returning machine gear designed for specific agricultural equipment, and the complex gearbox assembly that houses multiple gears, as well as the highly precise high precision gear used in demanding applications, each type plays a vital part in different machinery systems.

Mechanical systems, whether in industrial machinery or agricultural equipment, rely on a variety of components to function effectively. Among these essential parts, gears play a pivotal role in transmitting power and motion. From the gearbox gear that forms the core of power transmission within a gearbox to the drive gear that initiates the movement of a system, and the specialized bevel gears that change the direction of motion, gears are integral. In the agricultural sector, components like wheat machine gear and deep tiller gear are vital for the proper functioning of farming equipment, ensuring efficient crop processing and soil cultivation.

In the intricate world of mechanical engineering, certain components play a crucial role in ensuring the smooth operation of machinery, especially in the agricultural sector. From the gears that transfer power to the seats that facilitate meshing, each part contributes to the overall functionality and efficiency. Arc gear, meshing seat, harvester gear shaft, corn gear, and returning gear are among the key elements that are integral to various mechanical systems, particularly those found in agricultural equipment.

In the intricate world of mechanical engineering, a variety of specialized components work in harmony to ensure the smooth operation of machinery. From agricultural equipment to industrial gear systems, components like border inspection assembly, ring gear/gear ring, high frequency gear, meshing seat, and harvester input shaft play crucial and distinct roles. Each of these elements is designed with specific functions in mind, contributing to the overall performance, durability, and efficiency of the machinery they are part of.

International layout

Spread all over the world

our products are exported to various parts of the world. Currently, our products have been exported to more than 40 countries Our products cover Asia, Europe, Africa, South America, North America, and Oceania

Sign up

for Newsletter

Subscribe to the weekly newsletter for all the latest updates